India’s pharmaceutical industry is one of the fastest growing sectors in the Indian economy, with an average annual growth rate of 11 per cent in this decade. The growth of the industry is mostly driven by the surge in production, legislative reforms, the growth in contract manufacturing and outsourcing of clinical trials, R&D, foreign acquisitions and joint ventures by domestic players and other such factors. The industry is ranked fourth in the world in terms of production volume and 13th in domestic consumption value. The industry reached the USD 6.2 billion mark in 2006, which is about 1 per cent of the global industry size of USD 643 billion in 2006. The factors that could materialize this target include a world-class patent regime and an environment that fosters innovation and entrepreneurship.

Logistics is regarded as a crucial part of the Camy Pharmaceutical Co., since its activities are highly time sensitive. In addition, pharma products need temperature-controlled storage and distribution.

From the beginning, Camy has been focusing on the development of innovative activities such as high quality products and research and development. Since its inception, Camy has given due importance to logistics by focusing on activities at the supply chain and logistics level, such as delivering the product to the end customer at the right time and the right place, in a secure mode and at a competitive operational cost.

The most important supply chain factors at Camy are inventory reduction and bringing down the order cycle time. This is so because operational performance could be directly linked to logistics costs, while inventory reduction and the demand to decrease order cycle time are related to just-intime deliveries and supply chain speed.

There has been a paradigm shift in the supply chain process at Camy Pharmaceutical Co. Value- added tax (VAT), consolidation of pharma companies and the emergence of pharma retail chains are some of the factors driving the changes in the distribution cycle of Camy. Camy is continuously reforming its supply chain with changing regulations such as introduction of VAT in most of the states, the squeeze on domestic margins and increasing government pressure to contain retail drug prices. From the cost composition point of view, the major logistics costs at Camy include packaging

(product mix consisting of 350 formulations) and distribution (national coverage). Hence, logistics comprises 30-35 per cent of the costs in the pharmaceutical value chain.

Camy’s growth was mostly driven by a strategy of partnerships, quality acquisitions, brand building and manufacturing. On the supply chain management (SCM) front, Camy’s major challenge is to integrate its Indian and international businesses. Transportation of goods and inventory management are two areas the company is trying to further improve. With the implementation of SCM practices, the company could achieve significant results in the areas of raw material price reduction and inventory level optimization.

On the material front, Camy has 30 depots and spends 12 lakh per year on information communication. Within six months of the SCM applications, Camy has been able to reduce inventory from 40 per cent to 25 per cent, which is much lower than the industry’s average.

On the supply side, Camy deliberately reduced its supplier base to reduce the risk factors and the company shifted to bulk purchases from a few sources. They have adopted the single-window approach for procurement. This decision of the company has allowed it to gain bargaining power and reduced prices by 4-9 per cent for different raw materials. To improve the distribution service quality, the company has reduced the number of transporters in order to achieve reduced delivery time. This move of Camy has led to a clear improvement in quality and delivery of products. SCM has helped Camy to enhance their efficiency in managing resources and improving relationships.

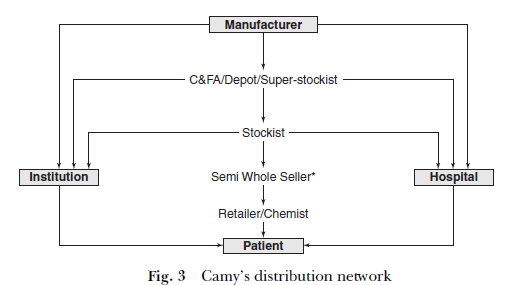

Logistics in pharma industry is very critical for providing the right medicine to the right patient at the right time, place and dosage, and most importantly, at the right price. Since business is highly competitive today, success largely depends upon the efficiency of the supply chain. The critical importance of the supply chain lies in its ability to maintain the complex network relationship among the organizations (drug manufacturers), trading partners to source raw materials, delivery products, retailers and hospitals (Figure 3).

With the growing competition among major pharmaceutical players in the industry, inventory control plays a significant role in pharma value chain as lots of inventory exists in the supply chain. For instance, out-of-stock situation in the existing business environment is unacceptable and research and development requires huge investment to bring products to market, when it finally arrives.

In addition, the margins on Camy products are very high. Around 30 per cent is shared by different channels of distribution. Hence, Camy was ready to spend to improve the efficiency of its supply chain. Camy with its supply chain initiative and efficient logistics is now ready to become globally competitive, as SCM contributed towards the enhancement of productivity as well as growth of the company.

Source: Sople V.V (2013), Logistics Management, Pearson Education India; Third edition.

10 Jun 2021

10 Jun 2021

10 Jun 2021

10 Jun 2021

10 Jun 2021

11 Jun 2021