A supply chain is a sequence of processes and flows that take place within and between different stages and combine to fill a customer need for a product. There are two ways to view the processes performed in a supply chain.

- Cycle View: The processes in a supply chain are divided into a series of cycles, each performed at the interface between two successive stages of the supply chain.

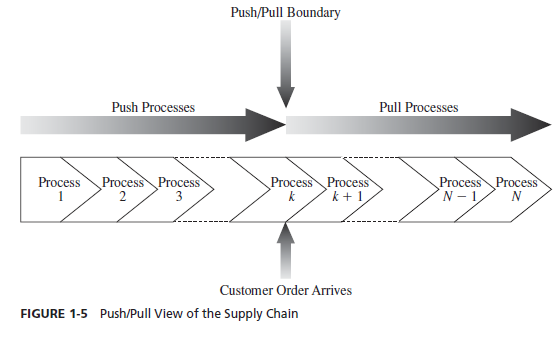

- Push/Pull View: The processes in a supply chain are divided into two categories, depending on whether they are executed in response to a customer order or in anticipation of customer orders. Pull processes are initiated by a customer order, whereas push processes are initiated and performed in anticipation of customer orders.

1. Cycle View of Supply Chain Processes

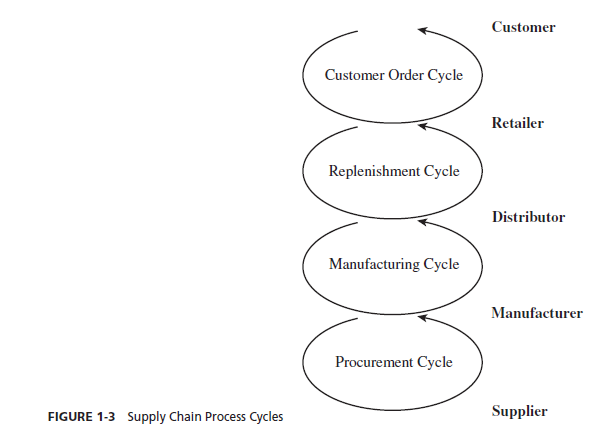

Given the five stages of a supply chain as shown in Figure 1-2, all supply chain processes can be broken down into the following four process cycles, as shown in Figure 1-3:

- Customer order cycle

- Replenishment cycle

- Manufacturing cycle

- Procurement cycle

Each cycle occurs at the interface between two successive stages of the supply chain. Not every supply chain will have all four cycles clearly separated. For example, a grocery supply chain in which a retailer stocks finished-goods inventories and places replenishment orders with a distributor is likely to have all four cycles separated. Dell, in contrast, bypasses the retailer and distributor when it sells servers directly to customers.

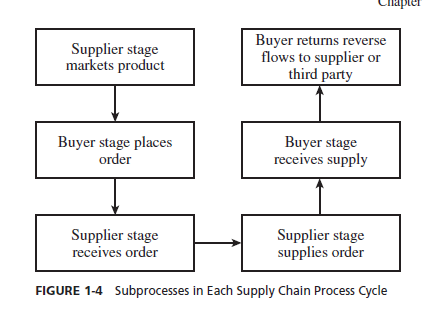

Each cycle consists of six subprocesses, as shown in Figure 1-4. Each cycle starts with the supplier marketing the product to customers. A buyer then places an order that is received by the supplier. The supplier supplies the order, which is received by the buyer. The buyer may return some of the product or other recycled material to the supplier or a third party. The cycle of activities then begins again. The subprocesses in Figure 1-4 can be linked to the source, make, deliver, and return processes in the supply chain operations reference (SCOR) model. The SCOR model provides a description of supply chain processes, a framework for relationships between these processes, and a set of metrics to measure process performance. The description of the supply chain in the SCOR model is similar to the cycle view of supply chains discussed in this section.

Depending on the transaction in question, the subprocesses in Figure 1-4 can be applied to the appropriate cycle. When customers shop online at Amazon, they are part of the customer order cycle—with the customer as the buyer and Amazon as the supplier. In contrast, when Amazon orders books from a distributor to replenish its inventory, it is part of the replenishment cycle—with Amazon as the buyer and the distributor as the supplier.

Within each cycle, the goal of the buyer is to ensure product availability and to achieve economies of scale in ordering. The supplier attempts to forecast customer orders and reduce the cost of receiving the order. The supplier then works to fill the order on time and improve efficiency and accuracy of the order fulfillment process. The buyer then works to reduce the cost of the receiving process. Reverse flows are managed to reduce cost and meet environmental objectives.

Even though each cycle has the same basic subprocesses, there are a few important differences among the cycles. In the customer order cycle, demand is external to the supply chain and thus is uncertain. In all other cycles, order placement is uncertain but can be projected based on policies followed by the particular supply chain stage. For example, in the procurement cycle, a tire supplier to an automotive manufacturer can predict tire demand precisely once the production schedule at the manufacturer is known. The second difference across cycles relates to the scale of an order. A customer buys a single car, but the dealer orders multiple cars at a time from the manufacturer, and the manufacturer, in turn, orders an even larger quantity of tires from the supplier. As we move from the customer to the supplier, the number of individual orders declines and the size of each order increases. Thus, sharing of information and operating policies across supply chain stages becomes more important as we move further from the end customer.

The detailed process description of a supply chain in the cycle view is useful when considering operational decisions because it clearly specifies the roles of each member of the supply chain. The cycle view is used by enterprise resource planning (ERP) systems to support supply chain operations.

2. Push/Pull View of Supply Chain Processes

All processes in a supply chain fall into one of two categories, depending on the timing of their execution relative to end customer demand. With pull processes, execution is initiated in response to a customer order. With push processes, execution is initiated in anticipation of customer orders based on a forecast. Pull processes may also be referred to as reactive processes because they react to customer demand. Push processes may also be referred to as speculative processes because they respond to speculated (or forecasted), rather than actual, demand. The push/pull boundary in a supply chain separates push processes from pull processes, as shown in Figure 1-5. Push processes operate in an uncertain environment because customer demand is not yet known. Pull processes operate in an environment in which customer demand is known. They are, however, often constrained by inventory and capacity decisions that were made in the push phase.

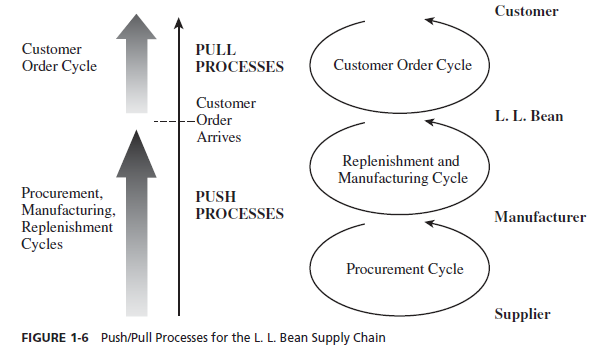

Let us compare a make-to-stock environment like that of L. L. Bean and a build-to-order environment like that of Ethan Allen to compare the push/pull view and the cycle view.

L.L. Bean executes all processes in the customer order cycle after the customer order arrives. All processes that are part of the customer order cycle are thus pull processes. Order fulfillment takes place from product in inventory that is built up in anticipation of customer orders. The goal of the replenishment cycle is to ensure product availability when a customer order arrives. All processes in the replenishment cycle are performed in anticipation of demand and are thus push processes. The same holds true for processes in the manufacturing and procurement cycles. In fact, raw material such as fabric is often purchased six to nine months before customer demand is expected. Manufacturing itself begins three to six months before the point of sale. The processes in the L. L. Bean supply chain break up into pull and push processes, as shown in Figure 1-6.

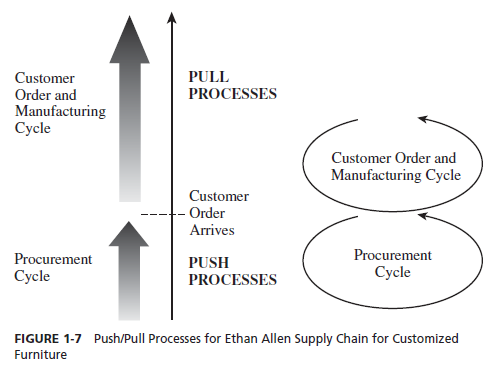

Ethan Allen makes customized furniture, such as sofas and chairs, for which customers select the fabric and finish. In this case, the arrival of a customer order triggers production of the product. The manufacturing cycle is thus part of the customer order fulfillment process in the customer order cycle. There are effectively only two cycles in the Ethan Allen supply chain for customized furniture: (1) a customer order and manufacturing cycle and (2) a procurement cycle, as shown in Figure 1-7.

All processes in the customer order and manufacturing cycle at Ethan Allen are classified as pull processes because they are initiated by customer order arrival. The company, however, does not place component orders in response to a customer order. Inventory is replenished in anticipation of customer demand. All processes in the procurement cycle for Ethan Allen are thus classified as push processes, because they are in response to a forecast.

A push/pull view of the supply chain is very useful when considering strategic decisions relating to supply chain design. The goal is to identify an appropriate push/pull boundary such that the supply chain can match supply and demand effectively.

The paint industry provides another excellent example of the gains from suitably adjusting the push/pull boundary. The manufacture of paint requires production of the base, mixing of suitable colors, and packing. Until the 1980s, all these processes were performed in large factories, and paint cans were shipped to stores. These qualified as push processes, as they were performed to a forecast in anticipation of customer demand. Given the uncertainty of demand, though, the paint supply chain had great difficulty matching supply and demand. In the 1990s, paint supply chains were restructured so mixing of colors was done at retail stores after customers placed their orders. In other words, color mixing was shifted from the push to the pull phase of the supply chain even though base preparation and packing of cans were still performed in the push phase. The result is that customers are always able to get the color of their choice, whereas total paint inventories across the supply chain have declined.

3. Supply Chain Macro Processes in a Firm

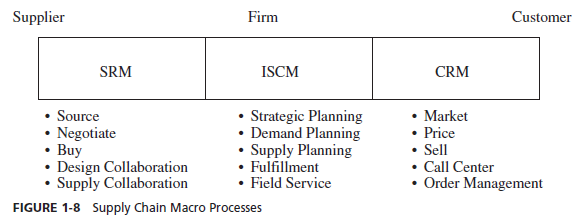

All supply chain processes discussed in the two process views and throughout this book can be classified into the following three macro processes, as shown in Figure 1-8:

- Customer Relationship Management (CRM): all processes at the interface between the firm and its customers

- Internal Supply Chain Management (ISCM): all processes that are internal to the firm

- Supplier relationship management (SRM): all processes at the interface between the firm and its suppliers

These three macro processes manage the flow of information, product, and funds required to generate, receive, and fulfill a customer request. The CRM macro process aims to generate customer demand and facilitate the placement and tracking of orders. It includes processes such as marketing, pricing, sales, order management, and call center management. At an industrial distributor such as W.W. Grainger, CRM processes include the preparation of catalogs and other marketing materials, management of the website, and management of the call center that takes orders and provides service. The ISCM macro process aims to fulfill demand generated by the CRM process in a timely manner and at the lowest possible cost. ISCM processes include the planning of internal production and storage capacity, preparation of demand and supply plans, and fulfillment of actual orders. At W.W. Grainger, ISCM processes include planning for the location and size of warehouses; deciding which products to carry at each warehouse; preparing inventory management policies; and picking, packing, and shipping actual orders. The SRM macro process aims to arrange for and manage supply sources for various goods and services. SRM processes include the evaluation and selection of suppliers, negotiation of supply terms, and communication regarding new products and orders with suppliers. At W.W. Grainger, SRM processes include the selection of suppliers for various products, negotiation of pricing and delivery terms with suppliers, sharing of demand and supply plans with suppliers, and the placement of replenishment orders.

Observe that all three macro processes are aimed at serving the same customer. For a supply chain to be successful, it is crucial that the three macro processes are well integrated. The importance of this integration is discussed in Chapter 10. The organizational structure of the firm has a strong influence on the success or failure of the integration effort. In many firms, marketing is in charge of the CRM macro process, manufacturing handles the ISCM macro process, and purchasing oversees the SRM macro process—with little communication among them. It is not unusual for marketing and manufacturing to have different forecasts when making their plans. This lack of integration hurts the supply chain’s ability to match supply and demand effectively, leading to dissatisfied customers and high costs. Thus, firms should structure a supply chain organization that mirrors the macro processes and ensures good communication and coordination among the owners of processes that interact with one another.

Source: Chopra Sunil, Meindl Peter (2014), Supply Chain Management: Strategy, Planning, and Operation, Pearson; 6th edition.

14 Jun 2021

15 Jun 2021

15 Jun 2021

15 Jun 2021

15 Jun 2021

15 Jun 2021