The need for selecting a suitable location arises because of three situations.

PLAN LOCATION AND LAYOUT

- When starting a new organisation, e., location choice for the first time.

- In case of existing organisation.

- In case of Global Location.

1. In Case of Location Choice for the First Time or New Organisations

Cost economies are always important while selecting a location for the first time, but should keep in mind the cost of long-term business/organisational objectives. The following are the factors to be considered while selecting the location for the new organisations:

- Identification of region: The organisational objectives along with the various long-term considerations about marketing, technology, internal organisational strengths and weaknesses, region- specific resources and business environment, legal-governmental environment, social environment and geographical environment suggest a suitable region for locating the operations facility.

- Choice of a site within a region: Once the suitable region is identified, the next step is choosing the best site from an available set. Choice of a site is less dependent on the organisation’s long-term strategies. Evaluation of alternative sites for their tangible and intangible costs will resolve facilities-location problem.

The problem of location of a site within the region can be approached with the following cost-oriented non-interactive model, i.e, dimensional analysis.

- Dimensional analysis: If all the costs were tangible and quantifiable, the comparison and selection of a site is easy. The location with the least cost is selected. In most of the cases intangible costs which are expressed in relative terms than in absolute terms. Their relative merits and demerits of sites can also be compared easily. Since both tangible and intangible costs need to be considered for a selection of a site, dimensional analysis is used.

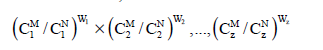

Dimensional analysis consists in computing the relative merits (cost ratio) for each of the cost items for two alternative sites. For each of the ratios an appropriate weightage by means of power is given and multiplying these weighted ratios to come up with a comprehensive figure on the relative merit of two alternative sites, i.e.,

C1M, c2m, ., CzM are the different costs associated with a site M on the ‘z’ different cost items.

CXN, C2n, …, CzN are the different costs associated with a site N and Wx, W2, W3, …, Wz are the weightage given to these cost items, then relative merit of the M and site N is given by:

If this is > 1, site N is superior and vice-versa.

When starting a new factory, plant location decisions are very important because they have direct bearing on factors like, financial, employment and distribution patterns. In the long run, relocation of plant may even benefit the organization. But, the relocation of the plant involves stoppage of production, and also cost for shifting the facilities to a new location. In addition to these things, it will introduce some inconvenience in the normal functioning of the business. Hence, at the time of starting any industry, one should generate several alternate sites for locating the plant. After a critical analysis, the best site is to be selected for commissioning the plant. Location of warehouses and other facilities are also having direct bearing on the operational performance of organizations.

The existing firms will seek new locations in order to expand the capacity or to place the existing facilities. When the demand for product increases, it will give rise to following decisions:

- Whether to expand the existing capacity and facilities.

- Whether to look for new locations for additional facilities.

- Whether to close down existing facilities to take advantage of some new locations.

2. In Case of Location Choice for Existing Organisation

In this case a manufacturing plant has to fit into a multi-plant operations strategy. That is, additional plant location in the same premesis and elsewere under following circumstances:

- Plant manufacturing distinct products.

- Manufacturing plant supplying to specific market area.

- Plant divided on the basis of the process or stages in manufacturing.

- Plants emphasizing flexibility.

The different operations strategies under the above circumstances could be:

- Plants manufacturing distinct products: Each plant services the entire market area for the organization. This strategy is necessary where the needs of technological and resource inputs are specialized or distinctively different for the different product-lines.

For example, a high quality precision product-line should not be located along with other product-line requiring little emphasis on precision. It may not be proper to have too many contradictions such as sophisticated and old equipment, highly skilled and semi-skilled personnel, delicates processes and those that could permit rough handlings, all under one roof and one set of managers. Such a setting leads to much confusion regarding the required emphasis and the management policies.

Product specialization may be necessary in a highly competitive market. It may be necessary to exploit the special resources of a particular geographical area. The more decentralized these pairs are in terms of the management and in terms of their physical location, the better would be the planning and control and the utilization of the resources.

- Manufacturing plants supplying to a specific market area: Here, each plant manufactures almost all of the company’s products. This type of strategy is useful where market proximity consideration dominates the resources and technology considerations. This strategy requires great deal of coordination from the corporate office. An extreme example of this strategy is that of soft drinks bottling plants.

- Plants divided on the basis of the process or stages in manufacturing: Each production process or stage of manufacturing may require distinctively different equipment capabilities, labour skills, technologies, and managerial policies and emphasis. Since the products of one plant feed into the other plant, this strategy requires much centralized coordination of the manufacturing activities from the corporate office that are expected to understand the various technological aspects of all the plants.

- Plants emphasizing flexibility: This requires much coordination between plants to meet the changing needs and at the same time ensure efficient use of the facilities and resources. Frequent changes in the long-term strategy in order to improve be efficiently temporarily, are not healthy for the organization. In any facility location problem the central question is: ‘Is this a location at which the company can remain competitive for a long time?’

For an established organization in order to add on to the capacity, following are the ways:

- Expansion of the facilities at the existing site: This is acceptable when it does not violate the basic business and managerial outlines, e., philosophies, purposes, strategies and capabilities. For example, expansion should not compromise quality, delivery, or customer service.

- Relocation of the facilities (closing down the existing ones): This is a drastic step which can be called as ‘Uprooting and Transplanting’. Unless there are very compelling reasons, relocation is not done. The reasons will be either bringing radical changes in technology, resource availability or other destabilization.

All these factors are applicable to service organizations, whose objectives, priorities and strategies may differ from those of hardcore manufacturing organizations.

3. In Case of Global Location

Because of globalisation, multinational corporations are setting up their organizations in India and Indian companies are extending their operations in other countries. In case of global locations there is scope for virtual proximity and virtual factory.

3.1. Virtual Proximity

With the advance in telecommunications technology, a firm can be in virtual proximity to its customers. For a software services firm much of its logistics is through the information/ communication pathway. Many firms use the communications highway for conducting a large portion of their business transactions. Logistics is certainly an important factor in deciding on a location—whether in the home country or abroad. Markets have to be reached. Customers have to be contacted. Hence, a market presence in the country of the customers is quite necessary.

3.2. Virtual Factory

Many firms based in USA and UK in the service sector and in the manufacturing sector often out sources part of their business processes to foreign locations such as India. Thus, instead of one’s own operations, a firm could use its business associates’ operations facilities. The Indian BPO firm is a foreign-based company’s ‘virtual service factory’. So a location could be one’s own or one’s business associates. The location decision need not always necessarily pertain to own operations.

3.3. Reasons for a Global/Foreign Location

3.3.1. Tangible Reasons

The trangible reasons for setting up an operations facility abroad could be as follows:

Reaching the customer: One obvious reason for locating a facility abroad is that of capturing a share of the market expanding worldwide. The phenomenal growth of the GDP of India is a big reason for the multinationals to have their operations facilities in our country. An important reason is that of providing service to the customer promptly and economically which is logistics-dependent. Therefore, cost and case of logistics is a reason for setting up manufacturing facilities abroad. By logistics set of activities closes the gap between production of goods/services and reaching of these intended goods/services to the customer to his satisfaction. Reaching the customer is thus the main objective. The tangible and intangible gains and costs depend upon the company defining for itself as to what that ‘reaching’ means. The tangible costs could be the logistics related costs; the intangible costs may be the risk of operating is a foreign country. The tangible gains are the immediate gains; the intangible gains are an outcome of what the company defines the concepts of reaching and customer for itself.

The other tangible reasons could be as follows:

- The host country may offer substantial tax advantages compared to the home country.

- The costs of manufacturing and running operations may be substantially less in that foreign country. This may be due to lower labour costs, lower raw material cost, better availability of the inputs like materials, energy, water, ores, metals, key personnel etc.

- The company may overcome the tariff barriers by setting up a manufacturing plant in a foreign country rather than exporting the items to that country.

3.3.2. Intangible Reasons

The intangible reasons for considering setting up an operations facility abroad could be as follows:

- Customer-related Reasons

- With an operations facility in the foreign country, the firm’s customers may feel secure that the firm is more accessible. Accessibility is an important ‘service quality’ determinant.

- The firm may be able to give a personal tough.

- The firm may interact more intimately with its customers and may thus understand their requirements better.

- It may also discover other potential customers in the foreign location.

- Organisational Learning-related Reasons

- The firm can learn advanced technology. For example, it is possible that cutting-edge technologies can be learn by having operations in an technologically more advanced country. The firm can learn from advanced research laboratories/universities in that country. Such learning may help the entire product-line of the company.

- The firm can learn from its customers abroad. A physical location there may be essential towards this goal.

- It can also learn from its competitors operating in that country. For this reason, it may have to be physically present where the action is.

- The firm may also learn from its suppliers abroad. If the firm has a manufacturing plant there, it will have intensive interaction with the suppliers in that country from whom there may be much to learn in terms of modern and appropriate technology, modern management methods, and new trends in business worldwide.

- Other Strategic Reasons

- The firm by being physically present in the host country may gain some ‘local boy’ kind of psychological advantage. The firm is no more a ‘foreign’ company just sending its products across international borders. This may help the firm in lobbying with the government of that country and with the business associations in that country.

- The firm may avoid ‘political risk’ by having operations in multiple countries.

- By being in the foreign country, the firm can build alternative sources of supply. The firm could, thus, reduce its supply risks.

- The firm could hunt for human capital in different countries by having operations in those countries. Thus, the firm can gather the best of people from across the globe.

- Foreign locations in addition to the domestic locations would lower the market risks for the firm. If one market goes slow the other may be doing well, thus lowering the overall risk.

Source: KumarAnil, Suresh N. (2009), Production and operations management, New Age International Pvt Ltd; 2nd Ed. edition.

It’s a shame you don’t have a donate button! I’d without a doubt donate to this excellent blog! I suppose for now i’ll settle for book-marking and adding your RSS feed to my Google account. I look forward to fresh updates and will share this site with my Facebook group. Chat soon!