Automatic Identification (Auto-ID) is the term used to describe the direct entry of data or information in the computer system, programmable logic controllers or any microprocessor-controlled device, without operating a keyboard. Auto-ID includes such technologies as bar coding, radio frequency identification (RFID), data communication, magnetic strip, and voice recognition. The usage of these technologies is based on the applications and the benefits derived. Auto-ID can be used for tracking railcars, a carton moving on the conveyor at a speed of 100 feet per minute, or a truck carrying goods on time-bound dispatches to the customers. The benefits of the Auto-ID are many, such as:

Accuracy. Error-free data entry is possible, as there is no human involvement.

Cost Saving. Reliable and correct information is made available to reduce the risk element in decision making on resource allocations. The technology also facilitates economies of scale for voluminous, repetitive operations.

- Voluminous data can be stored, retrieved and transferred within a fraction of a second.

- These technologies are user-friendly and provide ease in connectivity to a wider range of processing and controlling equipment.

Some of the popular Auto-ID technologies that are commonly used in logistics are given below.

1. Bar Coding

Bar codes are used for identification, handling, retrieval and storage of goods in warehouses and stores. It is the most popular identification technology in many applications. Individual inventory items, cartons or unitized packages are affixed with a bar code that can be read by a bar code scanner attached to an online computer system. Bar code is assigned to a particular inventory item to show its identity during storage, retrieval and dispatch. Bar codes are further used for communication of dispatched items for the preparation of bills by accounts departments and making periodic reports on inventory status and sales. The bar codes facilitate the tracking of specific items in the warehouse during inventory audit or material pick up. They also help in tracking a consignment during transportation/inspection at the customer end. The information that may be required generally relates to the country code, manufacturer’s name, product details, date of manufacture, material content, and so on. These details are required at the user’s end for inventory management and are in machine-readable codes in the form of bars and spaces.

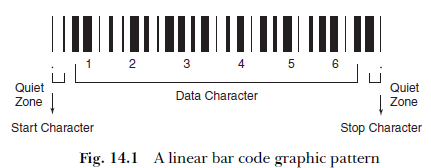

Bar codes are seen on all types of goods today. It is a sequence of parallel lines of different thickness with spaces in between. These bars are nothing but items of information in codified form, which can be decodified or read with the help of a scanner. In other words, bar code is a type of Morse code to put information of an item in code language. The bar code facilitates data accuracy, real-time data availability, uniformity and easy usage, which are recognized universally.

The history of the bar code can be traced back to its first application in the U.S. supermarkets in 1952. This system was developed for automatic capture of product information at billing counters in supermarkets. In 1960, it was used in food stores in the United States on a trial basis. However, due to the advancement in electronics and the formulation of the universal product coding (UPC) system, bar coding gained widespread acceptance in all supermarkets in the United States by 1974. Its usage in the manufacturing and service industries rapidly spread from 1980 onwards. In India, bar codes are used for limited applications by the limited companies. The pioneers in their use in India are Bajaj Auto Ltd. and Maruti Udyog Ltd., both of whom are using bar coding at their manufacturing plants for the past many years (Figure 14.1). [1] [2]

The bar codes have found applications in such diverse areas as the automobile industry, logistics, retail chains, electronics, defence, pharmaceutical industry, banking, consumer goods, libraries, airlines, passports, and so on. Today, the bar code is invariably used in practically all industries. Bar codes increase productivity in three ways: (1) speed, (2) accuracy and (3) reliability. Besides, they offer the following advantages:

- Facilitate easy identifi cation of inventory items during storage, retrieval, pickup, packing, dispatch, transit and inspection

- Reduce paper work and processing time leading to cost reduction

- Eliminate human error

- Increase the productivity of the warehouse

- Facilitate system automation

The bar codes are described by the symbologies used. Symbology means the pattern of lines and spaces used within the bar code to represent a number or an alphabet. There are 260 symbologies available for different applications for product recognition depending on the industry, business sector and products. Several factors play a role in the selection of the bar code suitable for your operations. Most industries have defined their bar code symbologies based on the following factors:

- Ease in usage of symbology in a particular product-industry

- Nature and type of data to be encoded

- Information fields to be encoded

- Feasibility of universal acceptability

- Location and size of the code on the product/item

The various bar code symbologies differ both in the way they represent data and in the type of data they can encode. Some symbologies can encode numbers, while others both numbers and letters, and some can encode letters, numbers as well as characters, that is, ASCII codes. The latest symbologies include multiple language options. Bar code symbologies can be divided into three broad categories:

- Linear symbologies consist of a single row of bars and can be read by a single-line scanner.

- A stacked symbology consists of several rows of bars and spaces and can be read by a multiple ID scanner with moving laser beam.

- These symbologies are in a polygonal array of data cells and are read from a 2D image scanner. Bar codes are also one-, two- or three-dimensional types depending on the symbology and its application. Various popular symbologies in use with their areas of application are indicated in Table 14.1.

The methodology in deciding the bar code is to study the requirements of the customer. The cost factor plays a major role in deciding what symbology to use. The typical application areas of pre-printed bar code labels are high-volume industries such as retail chains, FMCG, automobile spare parts and consumer durables industries. The second type of bar code label is prepared

on demand in accordance with the needs. This is invariably used in order processing wherein a bar code is assigned to a particular order received from the customer. Orders from different customers are unique in variety and volume of the product items. During the entire processing, the order is recognized with the bar code assigned to it. On demand bar codes are flexible but the cost is high.

Scanners are used for automatic identification of the bar code. The pattern of bars and spaces reflects the light pattern, which is converted into electronic signals to be decoded by the computer with reference to the memory file in the computer system. The choice of scanner is not dependent on the type of symbology in use. Two types of scanners are in use:

- Contact scanner

- Non-contact scanner

Scanning devices operate at different distances (called depth of field) from bar code labels. Scanners with zero depth of field are called contact scanners. Also available are remote scanners with depth of field of several feet. The scanners are used in retail stores at the billing counters. Bills will be prepared and inventory updates will be done automatically for the items identified. This allows precise tracking of stock keeping unit (SKU) sold and facilitates the quick replenishment of the same for communication to the suppliers. Thus, online tracking and replenishment of any number of SKUs, without error, is facilitated.

In stores where the volume of inventory handled is low, the contact scanner is in use. In libraries, for example, when books are issued and returned, the contact scanner is used for identification of the book title, author, subject, date of issue, and so on. For handling large volumes of inventory, the non-contact scanners are used. However, the condition here is that the stock/consignment has to pass through a fixed point on the conveyor. Say, if 1,00,000 packs are to be handled per day, the non-contact scanner will be ideal to sort or consolidate the various inventory items for packing and dispatching region-wise or customerwise.

EDI and bar coding can be linked together for improving the effectiveness of the system. For example, in the case of an electronic order from the customer, the supplier can assign a bar code for that order, which will include the product, quantity, price, delivery, and so on. This information on bar code label can be scanned at the time of dispatch to generate such documents as the packing list, invoice, bill of lading, excise gate pass and advanced shipping instruction to buyer.

Invariably, the bar code technology is used in procurement, processing and distribution operations in all industries. For system productivity improvement, bar code technology is widely used in modern warehousing and distribution operations in all industries. Today, the automobile industry and retail chains, where a wider variety of items with large volumes are handled under time constraints, are widely using the bar code technology.

When parts and components are bought from suppliers, they are assigned bar codes, which contain information on the item’s name, batch number, date of manufacture, order no., serial no.

and so on. This information in bar code form helps in identifying and tracking the part/item during its processing and further when it is in transit, as a finished product, to the customer. When goods enter through the conveyor in the warehouse, they are scanned either by a hand-held or noncontact scanner fixed alongside the conveyor. The information decoded by the scanner is immediately logged in the central computer. This helps in real-time update of the inventory records. Automatic sorting of the items on the conveyor can also be done for directing them to the assigned storage place in the warehouse or to the packing area for further dispatch to customers located in different geographical areas.

During order processing, the warehouse operator can prepare the order pickup slip, confirming the location of the items to be picked up for packing to the forklift operator. The bar code will help in identifying the items based on their date of entry into the warehouse or store. This will ease material storage, retrieval and dispatch in first-in-and-first-out (FIFO) inventory management system.

In the case of box containers or pallets with bar code labels, it becomes easier to identify the contents and check packed quantities, without breaking open the carton.

In logistics, bar coding makes identification of a particular item/part meant for a particular customer easier. It is very helpful for the export units where detailed information on items has to be maintained for the excise department, customs, sales tax department and export inspecting agencies. Bar coding eliminates a massive amount of paperwork and can avoid procedural delays in clearing the consignments. During the production process, the identification of in-process and finished items becomes easer because of bar coding. The various batches at different stages of manufacture can be easily tracked.

2. Radio Frequency Identification

RFID is currently one of the preferred forms of auto-identification of goods in the manufacturing, retailing and logistics industries. Such identification relies on storing and remotely retrieving data using a device called an RFID tag or transponder. The tag is an object that can be applied to or incorporated into a product, animal, or person for the purpose of identification using radio waves.

Most Radio Frequency Identification (RFID) tags contain at least two parts. One part consists of an integrated circuit for sorting and processing information, modulating and demodulating RF signals, and other specialized functions. The second one is an antenna for receiving and transmitting the signal. These are being used in passports—the first RFID passport was issued in Malaysia in 1998. It is also used in transportation payments. The payment card can be recharged with cash at an add-value machine or in the shop and can be read several centimetres from the reader. Delhi Metro uses this technology. High-frequency RFID tags are used on books in libraries and bookstores for jewellery or pallet tracking, building access control, airline baggage tracking and apparel and pharma items tracking.

3. Memory Buttons

These are used to supplant the common means such as bar coding to identify the goods. Memory buttons contain an encapsulated microprocessor. Several pages of information can be stored on a button that the reader can physically touch to extract the information. The buttons are suitable as a portable database for product identification in a harsh environment. These are also suitable for identification of storage retrieval and movement of large-size unit load containing a large number of items. The information regarding the contents of the package is stored in the microprocessor encapsulated in the button that is attached to the package. The information can be read with an electronic device, without touching the package. During order pickup, the forkliftman can easily identify the package with the reading device that is connected to the centralized computer. In the case of overseas dispatches, the memory buttons are keyed in with information required by various agencies, such as customs, inspection, shipping and forwarding, which facilitates speedy clearing of the consignment.

4. Radio Frequency Tags (RFT)

RFTs are used as an alternative to bar codes for communicating inventory data to the reader via radio waves. The reader is connected to the central computer. RFTs are pieces of silicon chip to store data in the microcircuit. They are programmable and have an erasable memory. Data is stored in coded form and communicated to the reader through radio waves. RFTs are available in “passive” or “active” form. The passive tags depend on energy from the reader to initiate communication. The active tags can directly communicate data to the reader at the centralized computer. Data are loaded in encrypted form on “read only” tags, which can be read but not altered. However, data on the read- write version can be erased or modified. The latter are priced higher than the read only tags. The reading range of these tags varies from 1 to 15 feet.

RFTs consist of two key components, namely, tags that act as data carrier and reader or antenna, which transfers information to and from the tag. The basic principle of the tag is that the antenna emits radio signals. RFTs are very useful accompaniments to truck shipments. The tag contains information on consigner, consignee, inventory items, quantity and value. RFTs can be helpful for quick clearances at octroi or customs posts. They do away with a lot of paperwork. In the warehouse bar codes can be applied to individual inventory items, while the RFTs can be used on pallets, containers, and so on. RFTs are more commonly mounted on the forklift or pallet truck or containers. They allow the staff to directly communicate with the warehouse computer within the effective communication range.

5. Voice Interactive System

Voice interactive system technology was developed for space travel application in the 1980s. However, the usage has now extended to various other fields such as legal, medical, manufacturing, warehousing, and so on. In warehouse application, it allows the worker or operator to communicate the data to the central computer without using the keyboard. It keeps the warehouse worker’s hands free to pick up, pack and inspect the goods. The forklift operator can read the part number, while driving the forklift or picking the inventory and move from one pallet to another. Due to online data transmission to the central computer real-time data updating is now possible.

The voice interactive system consists of a voice synthesizer and a headset. The operator creates a voice template for each word he utters during the dialogue with the computer. The system stores this template in the memory for use in future. Usage of this technology in warehouses allow low-skilled workers to interact with computers, which increase the speed of material picking and receiving and thereby raise warehouse productivity. As the speed of voice processing and memory capability increases, accuracy of spoken word conversion and speed of transmission of electronic signal will increase, enabling real-time data storage, processing and transmission required for productivity in logistics operations.

Source: Sople V.V (2013), Logistics Management, Pearson Education India; Third edition.

Definitely, what a splendid website and revealing posts, I will bookmark your site.All the Best!