Production/operations capabilities, limitations, and policies can significantly enhance or inhibit the attainment of objectives. production processes typically constitute more than 70 percent of a firm’s total assets. Thus, a major part of the strategy-implementation process takes place at the production site. Strategic production-related decisions on plant size, plant location, product design, choice of equipment, kind of tooling, size of inventory, inventory control, quality control, cost control, use of standards, job specialization, employee training, equipment and resource utilization, shipping and packaging, and technological innovation can determine the success or failure of strategy-implementation efforts.

Four production/operations issues—(1) restructuring/reengineering, (2) managing resistance to change, (3) deciding where/how to produce goods, and (4) managing an ESOP—are especially important for successful strategy implementation and are therefore discussed next.

1. Restructuring and Reengineering

Restructuring and reengineering are becoming commonplace on the corporate landscape across the United States and Europe. Restructuring involves reducing the size of the firm in terms of number of employees, number of divisions or units, and number of hierarchical levels in the firm’s organizational structure. This reduction in size is intended to improve both efficiency and effectiveness. Restructuring is concerned primarily with shareholder well-being rather than employee well-being.

The primary benefit sought from restructuring is cost reduction. For some highly bureaucratic firms, restructuring can actually rescue the firm from global competition and demise. But the downside of restructuring can be reduced employee commitment, creativity, and innovation that accompanies the uncertainty and trauma associated with pending and actual employee layoffs. Avon Products recently restructured, reducing its six commercial business units down to two—(1) Developed Markets and (2) Developing Markets—essentially going to a divisional by geographic region type structure.

The recent falling euro and weak economy in Europe forced many European companies to downsize, laying off managers and employees. This practice was historically rare in Europe because labor unions and laws required lengthy negotiations or huge severance checks before workers could be terminated. In contrast to the United States, labor union executives of large European firms sit on most boards of directors. Job security in European companies is slowly moving toward a U.S. business model, in which firms lay off almost at will. From banks in Milan to factories in Mannheim, European employers are starting to show people the door in an effort to streamline operations, increase efficiency, and compete against already slim and trim U.S. firms. European firms still prefer to downsize by attrition and retirement, rather than by blanket layoffs because of culture, laws, and unions.

In contrast to restructuring, reengineering is concerned more with employee and customer well-being than shareholder well-being. Reengineering involves reconfiguring or redesigning work, jobs, and processes for the purpose of improving cost, quality, service, and speed. Reengineering does not usually affect the organizational structure or chart, nor does it imply job loss or employee layoffs. Whereas restructuring is concerned with eliminating or establishing, shrinking or enlarging, and moving organizational departments and divisions, the focus of reengineering is changing the way work is actually carried out. Reengineering is characterized by many tactical (short-term, business-function-specific) decisions, whereas restructuring is characterized by strategic (long-term, affecting all business functions) decisions.

Developed by Motorola in 1986 and made famous by CEO Jack Welch at General Electric and more recently by Robert Nardelli, former CEO of Home Depot, Six Sigma is a qualityboosting process improvement technique that entails training several key persons in the firm in the techniques to monitor, measure, and improve processes and eliminate defects. Six Sigma has been widely applied across industries from retailing to financial services. For example, CEO Dave Cote at Honeywell and CEO Jeff Immelt at General Electric spurred acceptance of Six Sigma, which aims to improve work processes and eliminate waste by training “select” employees who are given judo titles such as Master Black Belts, Black Belts, and Green Belts. Target Corp. claims more than $100 million in savings over the past six years resulting from its Six Sigma program.

Six Sigma was criticized in a Wall Street Journal article that cited many example firms whose stock price fell for a number of years after adoption of Six Sigma. The technique’s reliance on the special group of trained employees is problematic and its use within retail firms such as Home Depot has not been as successful as in manufacturing firms.6

2. Manage Resistance to Change

No organization or individual can escape change. But the thought of change raises anxieties because people fear economic loss, inconvenience, uncertainty, and a break in normal social patterns. Almost any change in structure, technology, people, or strategies has the potential to disrupt comfortable interaction patterns. For this reason, people resist change. The strategic- management process can impose major changes on individuals and processes. Reorienting an organization to get people to think and act strategically is not an easy task. Strategy implementation can pose a threat to many managers and employees. New power and status relationships are anticipated and realized. New formal and informal groups’ values, beliefs, and priorities may be largely unknown. Managers and employees may become engaged in resistance behavior as their roles, prerogatives, and power in the firm change. Disruption of social and political structures that accompany strategy execution must be anticipated and considered during strategy formulation and managed during strategy implementation.

Resistance to change may be the single-greatest threat to successful strategy implementation. Resistance regularly occurs in organizations in the form of sabotaging production machines, absenteeism, filing unfounded grievances, and an unwillingness to cooperate. People often resist strategy implementation because they do not understand what is happening or why changes are taking place. In that case, employees may simply need accurate information. Successful strategy implementation hinges on managers’ ability to develop an organizational climate conducive to change. Change must be viewed by managers and employees as an opportunity for the firm to compete more effectively, rather than being seen as a threat to everyone’s livelihood.

Resistance to change can emerge at any stage or level of the strategy-implementation process. Although there are various approaches for implementing changes, three commonly used strategies are a force change strategy, an educative change strategy, and a rational or self-interest change strategy. A force change strategy involves giving orders and enforcing those orders; this strategy has the advantage of being fast, but it is plagued by low commitment and high resistance. The educative change strategy is one that presents information to convince people of the need for change; the disadvantage of an educative change strategy is that implementation becomes slow and difficult. However, this type of strategy evokes greater commitment and less resistance than does the force change strategy. Finally, a rational change strategy or selfinterest change strategy is one that attempts to convince individuals that the change is to their personal advantage. When this appeal is successful, strategy implementation can be relatively easy. However, implementation changes are seldom to everyone’s advantage.

Strategists can take a number of positive actions to minimize managers’ and employees’ resistance to change. For example, individuals who will be affected by a change should be involved in the decision to make the change and in decisions about how to implement the change. Strategists should anticipate changes and develop and offer training and development workshops so that managers and employees can adapt to those changes. They also need to effectively communicate the need for changes. Strategy implementation is basically a process of managing change.

The most successful organizations today continuously adapt to changes in the competitive environment. It is not sufficient today to simply react to change. Managers need to anticipate change and be the creator of change. Viewing change as a continuous process is in stark contrast to an old management doctrine regarding change, which was to unfreeze behavior, change the behavior, and then refreeze the new behavior. The new “continuous organizational change” philosophy should mirror the popular “continuous quality improvement philosophy.”

3. Decide Where and How to Produce Goods

In China, about 700,000 assembly workers at manufacturing contractors such as Foxconn put together Apple products. It would be virtually impossible to bring those jobs to the United States for at least three reasons. First of all, Foxconn—China’s largest private employer and the manufacturer of an estimated 40 percent of the world’s consumer electronic devices—pays its assembly workers far less than U.S. labor laws would allow. A typical salary is about $18 a day. Second, unlike U.S. plants, Foxconn and other Chinese manufacturing operations house employees in dormitories and can send hundreds of thousands of workers to the assembly lines at a moment’s notice. on the lines, workers are subjected to what most Americans would consider unbearable long hours and tough working conditions. That system gives tech companies the efficiency needed to race products out the door, so speed is a bigger factor than pay. Finally, most of the component suppliers for Apple and other technology giants are also in China or other Asian countries. That geographic clustering gives companies the flexibility to change a product design at the last minute and still ship on time.

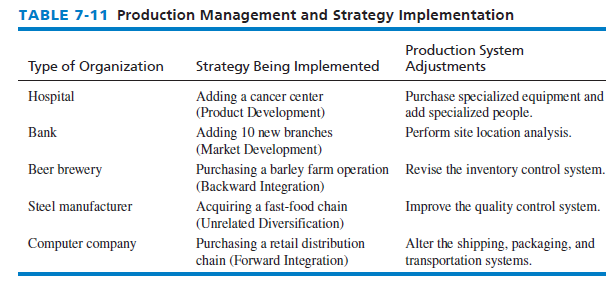

Examples of adjustments in production systems that could be required to implement various strategies are provided in Table 7-11 for both for-profit and nonprofit organizations. For instance, note that when a bank formulates and selects a strategy to add 10 new branches, a production-related implementation concern is site location. The largest bicycle company in the United States, Huffy, recently ended its own production of bikes and now contracts out those services to Asian and Mexican manufacturers. Huffy focuses instead on the design, marketing, and distribution of bikes, but it no longer produces bikes itself. The Dayton, Ohio, company closed its plants in ohio, Missouri, and Mississippi.

Just-in-time (JIT) production approaches have withstood the test of time. Just-in-time significantly reduces the costs of implementing strategies. Parts and materials are delivered to a production site just as they are needed, rather than being stockpiled as a hedge against later deliveries. Harley-Davidson reports that at one plant alone, JIT freed $22 million previously tied up in inventory and greatly reduced reorder lead time.

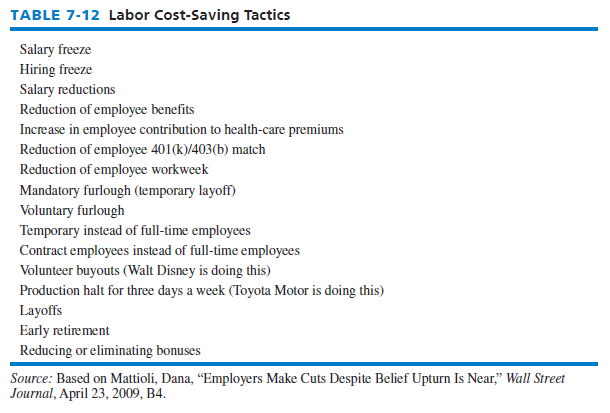

Factors that should be studied before locating production facilities include the availability of major resources, the prevailing wage rates in the area, transportation costs related to shipping and receiving, the location of major markets, political risks in the area or country, and the availability of trainable employees. Some of these factors explain why many manufacturing operations in China are moving back to Mexico, or to Vietnam, or even back to the United States. Table 7-12 lists ways that companies today are reducing labor, production, and operations costs to stay financially sound.

4. Employee Stock Ownership Plans (ESOPs)

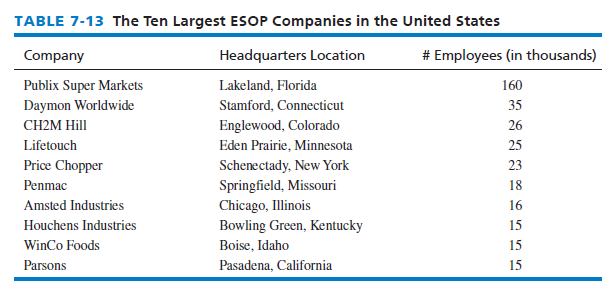

Besides reducing worker alienation and stimulating productivity, employee stock ownership plans (ESOPs) allow firms other benefits, such as substantial tax savings. An ESOP is a tax- qualified, defined-contribution, employee-benefit plan whereby employees purchase stock of the company through borrowed money or cash contributions. These plans empower employees to work as owners; this is a primary reason why the number of ESOPs have grown dramatically to more than 10,000 firms covering more than 14 million employees. Today, ESOPs control more than $600 billion in corporate stock in the United States. “The ownership culture really makes a difference, when management is a facilitator, not a dictator,” observes Corey Rosen, executive director of the National Center for Employee Ownership. The 10 largest employee-owned companies are listed in Table 7-13.

Source: David Fred, David Forest (2016), Strategic Management: A Competitive Advantage Approach, Concepts and Cases, Pearson (16th Edition).

This is a topic that’s near to my heart… Take care!

Exactly where are your contact details though?