Design and development approaches such as the quality function deployment show us what to solve, but not always how to solve the technology bottlenecks that arise. Most techniques rely on the experience of designers that may be limited to certain areas of expertise. Thus, a solution that might be simpler and cheaper using another technique could be missed. The technique of Teorija Rezbenija Izobretatelashib Zadach (TRIZ) can be used to explore design solutions in other fields.

Rockwell International’s Automotive Division was losing a competitive battle with a Japanese company over the design of brakes for a golf cart. Both Rockwell and the Japanese competitor were competing on redesigns of an automobile brake system but with smaller components. Using TRIZ, the problem was solved by redesigning a bicycle brake system with larger components. The result was a reduction in parts from 12 to four and a cost savings of 50 per cent.

1. Genrich S. Altshuller, the Father of TRIZ

Genrich S. Altshuller was born in the former Soviet Union in 1926. Interested in scientific research from a young age, his invention for scuba diving was devised when he was only 14 years old. His job in the Soviet Navy as a patent expert in the 1940s was to help inventors apply for patents. He was also often asked to assist in solving problems as well. His curiosity about problem solving led him to search for standard methods. According to Altshuller, a theory of invention should satisfy the following conditions:

- It should be a step-by-step procedure

- It should be able to direct everyone to the ideal solution

- It should be repeatable and reliable and not dependent on psychological tools

- It should be able to access and add to the body of inventive knowledge

- It should be familiar enough to inventors by following the general approach to problem solving

Altshuller screened over 200,000 patents looking for inventive problems and how they were solved. Altshuller defined an inventive problem as one in which the solution causes another problem to appear. For example, increasing the strength of a metal plate causing it to get heavier. Usually, inventors must resort to a trade-off and compromise between the features, thereby failing to achieve an ideal solution. In his study of patents, Altshuller found that many described a solution that eliminated or resolved the contradiction and required no trade-offs.

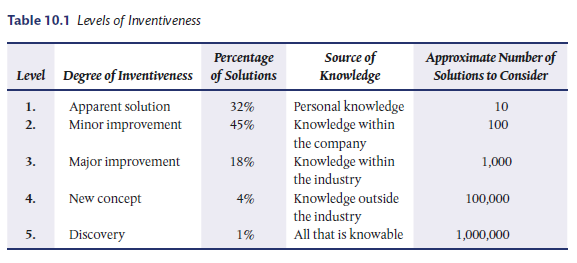

Altshuller categorized these patents in a novel way. Instead of classifying them by industry such as automotive, aerospace, etc. he removed the subject matter to uncover the problem-solving process. He found that often the same problems had been solved over and over again using one of only 40 fundamental inventive principles. Solutions could have been discovered more quickly and efficiently if later inventors had knowledge of the work of earlier ones. He categorized the solutions into five levels.5

Level one: Routine design problems solved by methods well known within the specialty. No invention needed. About 32 per cent of the solutions fell into this level.

Level two: Minor improvements to an existing system by methods known within the industry, usually with some compromise. About 45 per cent of the solutions fell into this level.

Level three: Fundamental improvement to an existing system by methods known outside the industry. Contradictions were resolved in the process. About 18 per cent of the solutions fell into this category.

Level four: A new generation that uses a new principle to perform the primary functions of the system. More solutions found in science than in technology. About four per cent of the solutions fell into this category.

Level five: A rare scientific discovery or pioneering invention of essentially a new system. About one per cent of the solutions fell into this category.

He also noted that with each successive level, the source of the solution required broader knowledge and more solutions to consider before an ideal one could be found. His findings are summarized in Table 10.1.

As per Altshuller’s tabulation, 90 per cent of the problems that engineers faced had been solved somewhere before. If engineers could follow a path to an ideal solution, starting with the lowest level, their personal knowledge and experience, and working their way to higher levels, most of the solutions could be derived from knowledge already present in the company, industry or in another industry. Altshuller distilled the problems, contradictions and solutions in these patents into a theory of inventive problem solving that he named TRIZ.

2. The TRIZ Process

Altshuller felt that an acceptable theory of invention should be familiar enough to inventors if they follow a step-by-step approach to problem solving:

Step 1 Identifying the problem: Boris Zlotin and Alla Zusman, Principal TRIZ scientists at the American company Ideation and students of Altshuller, developed an “Innovative Situation Questionnaire” to identify the engineering system being studied, its operating environment, resource requirements, primary useful function, harmful effects and ideal result.

Example: We can use the engineering system of a beverage can as an example to discuss the step-by-step TRIZ process. The function of a can is to contain beverages. Cans are stacked for storage purposes. The resources include weight of filled cans, internal pressure of cans and rigidity of can construction. The other parameters that come into play are the cost of materials for producing cans and the waste of storage space. The ideal result is a can that can support the weight of stacking to human height without damage to cans or the beverage in the cans.

Step 2 Formulate the problem: The problem should be restated in terms of physical contradictions. All problems that could occur should be identified. Could improving one technical characteristic to solve a problem cause other technical characteristics to worsen, resulting in the arising of secondary problems?

Example: We cannot control the height to which the cans will be stacked. The price of raw materials may compel us to lower costs. The can walls must be made thinner in order to reduce costs. However, if we make the walls thinner, it cannot support a large stacking load. Thus, the can wall needs to be thinner to lower material cost and thicker to support stackingload weight. If this physical contradiction can be solved, we will achieve an ideal engineering system.

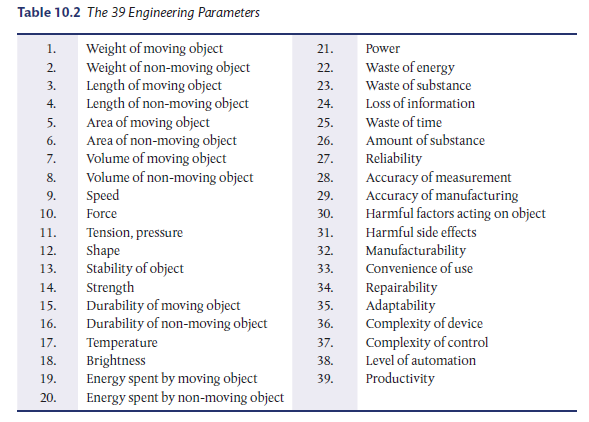

Step 3 Search for previously well-solved problem: Altshuller extracted 39 standard technical characteristics that cause conflict from over 1,500,000 world-wide patents. These 39 engineering parameters have been presented in Table 10.2. The next step is to find the contradicting engineering principles. The standard technical conflict should be found by first finding the principle that needs to be changed and then the principle that is an undesirable secondary effect.

Example: The standard engineering parameter that has to be changed to make the can wall thinner is “No. 4, length of a non-moving object.” If we make the can wall thinner, the stacking-load weight will decrease. The standard engineering parameter that is in conflict is “No. 11, stress.”

The standard technical conflict is that the more we improve the standard engineering parameter “length of a non-moving object,” the more the standard engineering parameter “stress” becomes worse.

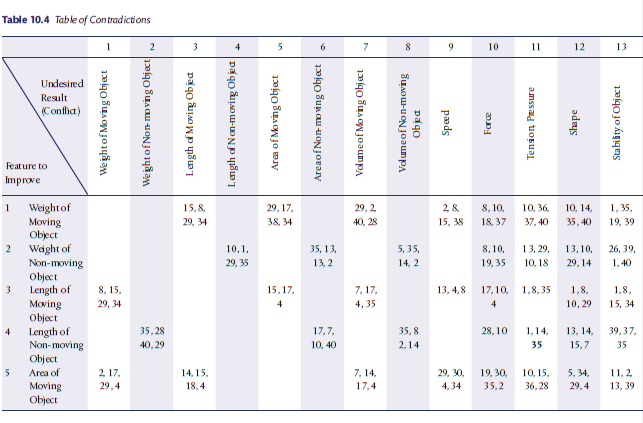

Step 4 Look for analogous solutions and adapt to the solution: Altshuller also extracted 40 inventive principles as shown in Table 10.3.6 These are hints that will help an engineer find a highly inventive (and patentable) solution to the problem. Altshuller also created a table of contradictions to find out which inventive principles to use. The table of contradictions lists the 39 engineering parameters on the X-axis (undesired secondary effect) and the Y-axis (features to improve). The appropriate inventive principles to use for a solution are listed in the intersecting cells.

Example: The engineering parameters in conflict for the beverage can are “No. 4, length of a non-moving object” and “No. 11, stress.” The feature to improve (Y-axis) is the can wall thickness or “No. 4, length of a non-moving object” and the undesirable secondary effect (X-axis) is the loss of load bearing capacity or “No. 11, stress.” Looking these up on the table of contradictions (Table 10.4), we find the numbers 1 (segmentation), 14 (spheroidality) and 35 (transformation of properties) in the intersecting cell.

Therefore, the solution for this problem can probably be arrived at by using inventive principles No. 1, No. 14 and No. 35 (Table 10.3). Applying inventive principle No. 1, segmentation can be carried out by—(a) dividing an object into independent parts, (b) making an object sectional and (c) increasing the degree of an object’s segmentation. By increasing the degree of an object’s segmentation, the wall of the can could be changed from a smooth continuous wall to a corrugated or wavy surface made up of many “little walls.” This would increase the edge strength of the wall, yet allow a thinner material to be used. Inventive principle No. 14 stands for spheroidality. This can be done by—(a) replacing linear parts or flat surfaces with curved ones; replacing cubical shapes with spherical shapes, (b) using rollers, balls spirals and (c) replacing linear motion with rotating movement by utilizing a centrifugal force.

The perpendicular angle at which most can lids are welded to the can wall can be changed to a curve using inventive principle No. 14. Inventive principle No. 35 refers to the transformation of the physical and chemical states of an object—changing an object’s aggregate state, density distribution, degree of flexibility, temperature. Thus, by using inventive principles No. 1, No. 14 and No. 35, the wall of the can can be designed to become thinner to lower material cost and thicker to support stacking-load weight.

Source: Poornima M. Charantimath (2017), Total Quality Management, Pearson; 3rd edition.

I like the efforts you have put in this, appreciate it for all the great articles.