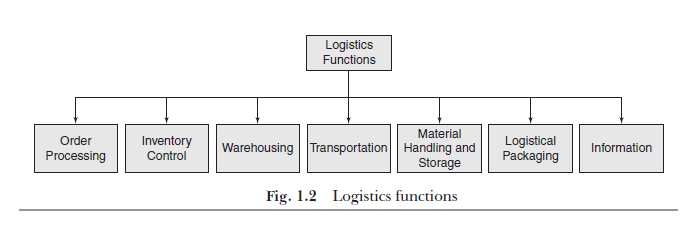

Logistics is a process of movement of goods across the supply chain of a company. However, this process consists of various functions that have to be properly managed to bring effectiveness and efficiency to the supply chain of the organization. The major logistical functions are shown in Figure 1.2.

1. Order Processing

It is an important task in logistics operations. The purchase order placed by a buyer to a supplier is an important legal document of the transactions between the two parties. This document incorporates the description or technical details of the product to supply, price, delivery period, payment terms, taxes, and other commercial terms as agreed. The processing of this document is important as it has a direct relationship with the order or the performance cycle time, which indicates the time when the order is received and when the material is received by the customer. The order processing activity consists of the following steps:

- Order checking for any deviations in agreed-upon or negotiated terms

- Prices, payment, and delivery terms

- Checking the availability of materials in stocks

- Production and material scheduling for shortages

- Acknowledging the order indicating deviations, if any

The above process consumes more time if paperwork is involved. If the processing of the order is slow and complicated, it will have a direct effect on the delivery period committed. It may increase the transportation cost in order to deliver the material faster to compensate for the delays in the order processing operation.

Order processing is a routine operation but requires a great deal of planning, training of people involved, and investment in the system to bring efficiency and accuracy to it. In a large organization where thousands of orders are received each day, it becomes impossible to manually register the order and process the order quickly and correctly. In such a situation, a system capable of handling such voluminous work with minimum or no human involvement is a necessity. In addition, due to competitive pressure, the order fulfilment cycle has to be shortened to have an edge over the rival firms for retaining the customers. The only solution is to devise an order processing system ensuring efficiency and accuracy, but with minimal investment costs.

2. Inventory Management

Inventory management is to keep enough inventory stocks to meet customer requirements, and simultaneously its carrying cost should be the lowest. It is basically an exercise of striking a balance between the customer service for not losing market opportunity and the cost to meet the same. The inventory is the greatest culprit in the overall supply chain of a firm because of its huge carrying cost, which indirectly eats away the profits. It consists of the cost of financing the inventory, insurance, storage, losses, damages, and pilferages. The average cost of carrying inventory varies from 10 to 25 per cent of the total inventory per year depending on the products. In the case of perishable products, it is on the higher side. Even though inventory is a major concern, without it a firm cannot meet the regular and timely product requirements of its customers.

There are two approaches to inventory management: one is cost approach and the other is customer satisfaction. Business firms try to strike a balance between the two. Due to advance communications and computing facilities, some business firms in business-to-business (B2B) markets are operating on a zero-inventory level by adopting the JIT (just-in-time) technique. But this is possible with co-partnership between the purchaser and the supplier, and they communicate on a real-time basis.

3. Warehousing

Warehousing is the storing of finished goods until they are sold. It plays a vital role in logistics operations of a firm. The effectiveness of an organization’s marketing depends on the appropriate decision on warehousing. In today’s context, warehousing is treated as a switching facility rather than a storage place. It is a major cost centre, and many problems at the customer end are directly a result of improper warehousing management. Warehousing is the key decision area in logistics. The major decisions in warehousing are:

- Location of warehousing facilities

- Number of warehouses

- Size of the warehouse

- Warehouse layout

- Design of the building

- Ownership of the warehouse

Warehousing is an important component of logistics as it is directly linked to the ability of a firm to deliver the desired level of customer service. The ownership of a warehouse is private, public, or contractual. Each has advantages and disadvantages associated with it, and a firm has to choose the best options depending on its objectives and the resources available. However, the decision on warehousing requires proper planning and analysis, as well as help from experts in real estate, industrial engineering, and operations research.

4. Transportation

For movement of goods from the supplier to the buyer, transportation is the most fundamental and important component of logistics. When an order is placed, the transaction is not complete till the goods are physically moved to the customer’s place. The physical movement of goods is through various transportation modes. For low unit value products, the transportation cost component is 20 per cent of the product cost. In logistics costs, its share varies from 65 to 70 per cent in the case of mass-consumed, very low unit-priced products.

Firms choose the mode of transportation depending on the infrastructure of transportation in the country or region, Cost is the most important consideration in the selection of a particular mode of transport. However sometimes urgency of the goods at the customer end overrides the cost consideration, and the goods are sent through the fastest mode, which is an expensive alternative.

The consideration of whether the firm should have its own fleet or go in for outsourcing depends on investment, operating costs, expertise, and reliability. The common modes available are road carriers, railways, airways, ships, pipelines, and ropeways. Depending on the customer requirements and the availability of transportation infrastructure and its reach and cost, firms decide on the mode with an optimum cost under the given product-market conditions.

5. Material Handling and Storage System

The speed of the inventory movement across the supply chain depends on the material handling methods. An improper method of material handling will add to the product damages and delays in deliveries and incidental overheads. Mechanization and automation in material handling enhance the logistics system productivity. Other considerations for selection of a material handling system are the volumes to be handled, the speed required for material movement, and the level of service to be offered to the customer.

The storage system is important for maximum space utilization (floor and cubic) in the given size of a warehouse. The material handling system should support the storage system for speedy movement (storage and retrieval) of goods in and out of the warehouse.

6. Logistical Packaging

Logistical or industrial packaging is a critical element in the physical distribution of a product, which influences the efficiency of the logistical system. It differs from product packaging, which is based on marketing objectives. However, logistical packaging plays an important role in damage protection, ease in material handling, and storage space economy. The unitization of load has a major bearing on logistical packaging with regard to the packaging cost.

7. Information

Logistics is basically an information-based activity of inventory movement across a supply chain. Hence, an information system plays a vital role in delivering a superior service to the customers.

Use of IT tools for information identification, access, storage, analysis, retrieval, and decision support in logistics is helping business firms to enhance their competitiveness.

Source: Sople V.V (2013), Logistics Management, Pearson Education India; Third edition.

Pretty! This was an incredibly wonderful article.

Many thanks for supplying these details.

Way cool! Some very valid points! I appreciate you writing this

write-up and also the rest of the website is really good.

Hey there! This post could not be written any better! Reading this post reminds me of my good old room mate! He always kept talking about this. I will forward this post to him. Fairly certain he will have a good read. Thanks for sharing!