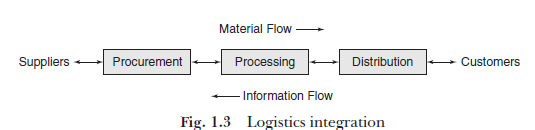

Logistics is an information-based process of material movement from a supplier to the manufacturer and to the customers. Hence, for business excellence, logistics operations need to be integrated on the following two fronts:

- Integration of logistics into the business

- Integration of components of logistics

Any business process consists of a set of activities that include raw material procurement, conversion, and the distribution of finished products for selling. To accomplish the objective of making available the right product at the right place and at the right time with less cost, the help of another process called logistics is needed to take care of the material storage and movement across three stages of a business process. The objectives of the business will not be achieved unless logistics is integrated into the business process. The integration will make the business process run as a chain rather than isolated process elements. The logistics process is a set consisting of a number of activities, including warehousing, material handling, storage, packaging, transportation, and information flow (see Figure 1.3).

For a logistics operation to run smoothly, proper integration among the components of the logistics process is imperative. The efficiency and effectiveness of the entire system depend on how individual elements get coordinated and work as a system and not as functional silos.

In an integrated logistics process, a close coordination between inventory flow and information flow is essential for system efficiency and effectiveness. For a manufacturer, the inventory flow starts after the material is shipped from a supplier to the processing or manufacturing centre and ends with the delivery of the finished product to the customer or user. In the case of a retailer, the logistics process starts after the material is dispatched from the manufacturer or wholesaler and ends with final delivery to the user. The volume of logistical activities varies with the width of the supply chain, the product category, and the volume of the business.

In a business process, there is continuous value addition at each stage of inventory transformation until it is finally delivered to the customer. Logistics supports the value creation process and hence it requires continuous attention of the management. For the focused attention, logistics activities can broadly be divided into three areas of business operations wherein the logistics needs are quite different.

1. Procurement

It is also known as buying or purchasing activity. The material movement from suppliers to the buyer comes under the purview of inbound logistics. The raw material, components, parts, and

consumables required for manufacturing operations should be available at the plant at the start of production schedules. The logistics activities include transportation and storage. The focus here is on a timely movement of the goods in an economic load size for transportation. Procurement is concerned with availability of desired material for the manufacturing in the right quantity. To save on the inventory carrying costs, the frequent but small lot sizes are planned. However, with an increased transportation frequency, the freight charges may go up, which may be offset by savings on inventory carrying costs.

2. Processing

The logistics operation in manufacturing is concerned with movement of in-process or work-inprogress inventory. Logistics here helps in preparing production scheduling. It is concerned with availability of inventory for the products to be manufactured, the places where they are manufactured, and the timings when they are manufactured. For example, the sub-assemblies for the truck will be manufactured at the decentralized locations from where these have to be brought to the main plant for carrying out the main truck assembly. The process logistics here takes care of the movement of the right parts and components to the respective sub-assembly plants and from there to the main assembly plant as and when required per the production schedules. Process logistics takes care of the movement of inventory for requirements of the internal customer where the degree of uncertainty is very low because the manufacturing operations are under the control of management.

3. Distribution

The movement of finished goods from a manufacturing plant to the customer or user comes under the purview of outbound logistics. The availability of material at the point of sale and the time it is required by the customer is vital for an enterprise to encash the opportunity. The material may be required at various places in the distribution channels. The requirement of each of the channel members may be different in terms of quantity, product variety, frequency of delivery, transportation, and so on. The outbound logistics ensures movement of the material per the requirements at the right place and at the right time, but with the minimum cost.

The logistical activities at three places—procurement, processing, and distribution—in a supply chain overlap, but the requirements are different. Hence, the prime goal of the integrated logistics should be to coordinate the inventory movement across the supply chain for system effectiveness and efficiency to gain a competitive advantage.

Source: Sople V.V (2013), Logistics Management, Pearson Education India; Third edition.

Whats Happening i am new to this, I stumbled upon this I’ve found It absolutely helpful and it has helped me out loads. I am hoping to contribute & assist different customers like its aided me. Good job.