Re-engineering requires a massive change in the re-engineer involving lay-offs and huge investments in automation and information technology. However, proper re-engineering of business processes will bring big benefits to the company. Re-engineering should start with a clean state approach. It requires selection and focus on critical business processes, process analysis, cross-functional teams, support from a strong leadership and the use of information technology as enablers. These are explained below:

1. Clean Slate Approach

This is the original philosophy of BPR that challenges the fundamentals of a process. It involves a fundamental questioning of the techniques and entails suitable benchmarking to comprehend the full details of the current processes and to assess gap areas from the customer’s perspective. Re-engineering starts from the future and work backwards unconstrained by current approaches.

2. Critical Processes

The emphasis of re-engineering should be on identifying core business processes rather than the functional and support processes, which have a greater scope for breakthrough improvements rather than incremental improvement. Re-engineering should be assured for essential processes such as new product development or customer service that provides what the customer wants at the price the customer will pay.

3. Process Analysis

A re-engineering team must have a clear understanding of the current process—what it does, how well it performs and what factors affect it. Such an understanding can reveal areas in which new thinking will provide breakthrough improvement. The team must work on every procedure involved in the process throughout the re-engineer, recording each step, questioning why it is done and then eliminating it if it isn’t really necessary.

4. Cross-functional Teams

A team consisting of members from each functional area affected by the process is required for carrying out a re-engineering project. Re-engineering works best at high involvement workplaces, where self-managing teams and employee empowerment are promoted and nurtured. Top-down and bottom-up initiatives can be combined—the top-down for performance targets and the bottom-up for deciding how to achieve the targets.

5. Strong Leadership

The top management should provide the required resources and create a sense of urgency, making a case for change that is compelling. Strong leadership by senior executives is required to execute a re-engineering project. The leadership should set and monitor key performance objectives for the process.

6. Information Technology

Information technology is a key enabler of BPR. Information should be captured once, at the source and be reused often. Information should not be keyed-in more than once. Information processing work should be merged with the real work that produces information. Most re-engineering projects design processes around information flows such as customer order fulfillment.

7. Rules of BPR

BPR was implemented for achieving a drastic improvement in the processes so that customer requirements of speed, innovation, quality, service and customization were met. In order to achieve this, Michael Hammer proposed seven new rules of doing work. These are related to who does the work, where and when it is done and the mode of information capturing and integration. The seven rules are given below:

7.1. Rule 1: Organize Around Outcomes, Not Tasks

BPR requires an integration of various tasks and activities to rationalize the process. The new job created should involve all the steps required to create an outcome. Organizing around outcomes eliminates activities that do not add value, resulting in better quality, greater speed, productivity and customization.

7.2. Rule 2: Have Those Who Use the Output of the Process Perform the Process

People involved in the process should actually perform the work at the optimal location. Multi-skilled workers should be used as process owners. This will ensure that functional- oriented re-engineers become new process-oriented and customer centric in nature. For example, customers can be trained to perform simple repairs and suppliers can be asked to manage inventory.

7.3. Rule 3: Merge Information Processing Work with the Real Work that Produces the Information

This means that people who capture the information should be responsible for processing it. This reduces errors by removing the numbers of external contact points for a process.

7.4. Rule 4: Treat Geographically Dispersed Resources as Though they Work in a Centralized Manner

This requires tremendous network connectivity. Centralized databases and telecommunication networks enable companies to link separate units or individual field personnel, providing them with economies of scale while maintaining their individual flexibility and responsiveness to customers. Digital information sharing should also be initiated.

7.5. Rule 5: Link Parallel Activities Instead of Integrating their Results

Perform parallel instead of sequential tasks and integrate their results to cut down end- to-end business process cycle time. Such parallel activities should be linked continuously and coordinated during the process.

7.6. Rule 6: Make the Decision Point where the Work Is Performed and Build Control in the Process

Decision making should be made part of the work performed. Employees should be empowered and support should be provided to help them make decisions. Today, this is possible with a knowledgeable workforce and cutting edge technology. Control systems should be made part of the process.

7.7. Rule 7: Information Should Be Captured Once at the Source

Information should be captured once at the source and reused often. Information should not be keyed-in more than once to avoid errors.

BPR principles can be summarized as below:

- Several jobs are combined into one.

- Workers make the decisions.

- The steps in a process are performed in a natural order.

- Processes have multiple versions.

- Work is performed where it makes the most sense.

- Checks and controls are reduced.

- Reconciliation is minimized.

- A case manager is the single point of contact.

- Hybrid centralized/decentralized operations are prevalent.

The multiplier effects of BPR give an impetus to the industry through impressive successes across companies. For example, radical and fundamentally new BPR methods enabled Motorola to slash order fulfillment for paging devices from 30 days or more to 28 minutes and Progressive Insurance to slash the claims settlement from 31 days to 4 hours.

8. Benefits of BPR

The concept of BPR is actually industry-neutral. The re-engineers most likely to gain from BPR are usually the kinds that have business units spread across the world. This kind of a company will also have a number of business processes that cut across them. Each of these business processes will generate large amounts of vital information in the internal reengineered units. This will result in large information silos, which will create a fair amount of complications and inefficiencies. At this stage, companies must step back and look at their business models to identify the key business processes in their value chains.

BPR will help re-engineers extract better performance from their existing systems and set up and introduce significant improvements. For example, banks can strengthen their business processes and use BPR for loan approval and processing. Manufacturing companies can use BPR to get insights into their inventory management process. Some of the more common benefits are:

- Elimination of non-value adding activities and achievement of cost savings in the long run.

- Adaptation to change that enables growth of new businesses.

- Creation of product differentiation on the basis of cycle time.

- Achievement of satisfaction for employees as work becomes more meaningful.

- Empowerment of employees resulting in swift decision making.

- Improvement of efficiency, for example, reduced time to market, providing quicker response to customers.

- Improvement in efficiency bringing about an increase in effectiveness, for example, delivering higher quality.

The following tangible benefits that improve the competitive positioning of firms have been reported:

- Reduction in product development time by 40-60 per cent

- Reduction in response time by 40-60 per cent

- Reduction in lead time by 70-90 per cent

- Reduction in unit cost by 15-25 per cent

- Reduction in inventory and other related costs by 60-80 per cent

As many as 65 per cent of Fortune 500 companies claimed to have initiated re-engineering efforts by 1993. According to Taco Bell, BPR directly lead to a 22 per cent growth in revenues because of the focus on activities that bring value to the customer. Re-engineering at Ford Motor Company improved its invoice processing systems so that the task was accomplished by 75 per cent fewer people and more accurate financial information was produced as a result. At IBM Credit Corporation, a credit insurance process that used to take two weeks to complete now took just four hours with a 100-fold increase in productivity.

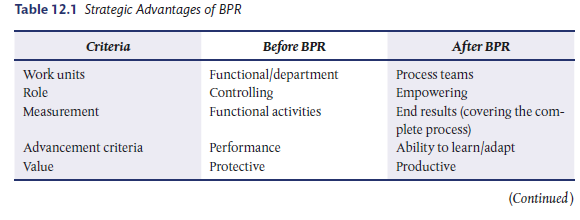

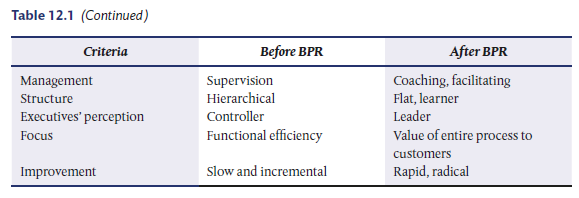

Some of the famous success stories of BPR are Walmart, Hewlett-Packard, Singapore National Library Board and IBM. Walmart reduced restocking from six weeks to 36 hours; Hewlett Packard’s assembly time for server computers touched a new low of four minutes. Singapore National Library Board improved its operation efficiency drastically. The strategic advantages of BPR (before and after implementation) are given in Table 12.1.3 Box 12.2 discusses the applications of BPR at HCL.

Box 12.2 Application of Re-engineering and Integration at HCL

HCL, founded in 1976, is a leading global technology and IT enterprise with annual revenues of USD 5 billion. The HCL enterprise comprises two companies listed in India—HCL Technologies and HCL Infosystems.

The company has embraced applications modernization and re-engineering initiatives to devise ways to upgrade business processes and services to keep pace with the rapidly moving business world and its strategies. Recognizing this, it has redefined its IT needs and is re-engineering its existing legacy applications to attain long-term business objectives. HCL works with its customers to devise solutions that help in attaining the future business goals and gaining a long-term edge over competition. It helps customers in their application re-engineering and modernization initiatives and provides solutions that enable them to fundamentally redesign a strategic roadmap for the future.

At HCL, processes and approach are focused on re-engineering the existing applications of the clients and developing future-enabled solutions that create and deliver long-term value to clients. HCL has always had the ability to read ahead of any market inflexion point and adapt itself to derive maximum advantage. The result is that HCL is one of the pioneers in technology today.

Source: Poornima M. Charantimath (2017), Total Quality Management, Pearson; 3rd edition.

The very heart of your writing while appearing agreeable at first, did not really work well with me after some time. Somewhere throughout the paragraphs you were able to make me a believer but just for a while. I still have got a problem with your leaps in assumptions and you might do nicely to help fill in those gaps. When you actually can accomplish that, I could undoubtedly end up being amazed.