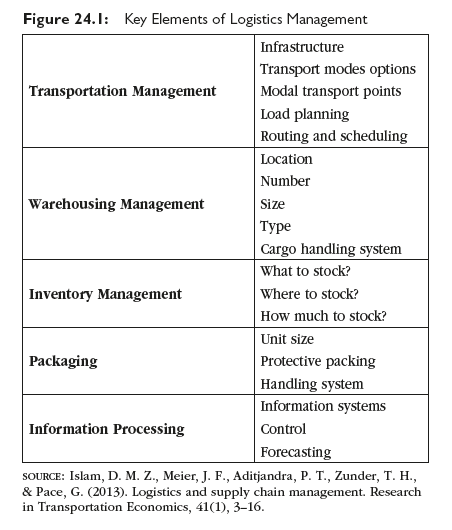

The objective of logistics management is to facilitate an efficient transportation or timely movement of products from one place to another with optimum inventory level consistent with customer service goals at lowest possible total logistics cost. The Council of Logistics Management (1998) defines logistics as, “the process of planning, implementing, and controlling the efficient, effective flow and storage of goods, services, and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements. Note that this definition includes inbound, outbound, internal and external movements, and the return of materials for environmental purposes.”7 The elements of logistics management are transportation management, warehousing management, inventory management, packaging, and information processing (Figure 24. 1).

Transportation Management. Transportation is the primary element of logistics. Transportation costs take one-third of the amount in the logistics costs and transportation management influences the performance of the complete logistics system. Transportation is required in the whole logistics chain, from manufacturing to delivery to the final consumers and returns. The key features of transportation management consist of transport infrastructure, modes of transport (such as road, rail, air, pipeline, and water), type of delivery (express, normal), load planning, routing, and scheduling. A transportation cost is incurred when product is transported from one place to another place. For example, when a product is moved from the manufacturing plant to the warehouses and then from the warehouses to customers.

Transportation cost is calculated as a function of unit rate, distance, and quantity of product. While one of the objective of transportation management is to reduce the inventory storage time, it is also important for transportation efficiency to supply the products to the customers in a short period of time. Here, routing and scheduling of vehicles play a critical role.

The transportation management is facing intense changes because of digital transformation, changing customer expectations, new market entrants, and new online business models. A company can improve its financial performance with efficient management of transportation and shipping costs. Many companies are collaborating with third-party logistics (3PL) and fourth-party logistics (4PL) providers to effectively manage their logistics and transportation costs. The 3PL company works with transporters to maintain another company’s logistics 4PL is an integrator that accrues resources, capabilities, and technologies to offer complete supply chain solutions to companies. 4PL operation costs are more than the 3PL costs as it requires the building of an entire supply chain.

Warehousing Management. Warehousing Management is an efficient way to balance the demand and supply of goods. It plays a vital role to have the right products available at the right place at the right time. A warehouse is used for receiving, storing, and distributing products. The important considerations of warehouse management include the location, number, size, type of storage, and material handling equipment.[2] The location and number of warehouses is a major factor as it directly affects the inventory costs, transportation costs, and warehousing costs. The location of the warehouse is also related to the time of delivery. Improper warehousing or delayed shipment of products can result in stock-outs in the market. This is when the channel partners do not fulfill the customers’ orders because ofa shortage of goods. Stock-outs not only result in the loss of sales but can also affect customer satisfaction. The increase in the number of warehouses can help to reduce the possibilities of stock-outs and will also contribute to reducing the time and costs of transportation. On the other hand, the increase in the number of warehouses can increase the warehousing costs. A company has to decide an optimal number of warehouses at the optimal number of locations by identifying the optimal trade-offs between the number of warehouses and customer service levels.

Warehousing processes like order consolidation, product mixing, and cross-docking help to add value to the logistics management. It is important to assign warehouse resources efficiently and effectively to enhance the productivity and reduce the operation costs of the warehouse.[3] [4] Many companies are adopting warehouse management systems to keep a record of inventory levels and different SKUs by using the barcodes and Radiofrequency Identification (RFID) technology.

Inventory Management. Inventory management is the process of regulating the constant flow of products into and out of the existing inventory. Inventory management is probably one of the most crucial activities in the logistics management as it is directly related to the profitability of an organization. The strategic decisions in inventory management include what to stock, how much to stock, and where to stock. Inventories are like opportunity costs, and high levels of inventory can lower the profits. Efficient inventory management will maintain a sufficient level of stocks that is neither too high to increase the inventory carrying costs nor too low to cause shortages in the market.

An important objective of inventory management is to maintain a perfect balance between customer service and inventory costs. It is essential to understand the time it takes for a company to process an order and execute a delivery. Another importan factor is to determine the planning and timing of an order and how many units must be ordered to keep the inventory at an optimum level. Demand and supply uncertainty is one of the key challenges in the inventory management, and many companies keep buffer inventory in addition to the minimum inventory to avoid the possibility of shortages.

Packaging. The essential functions of packaging are protection, containment, preservation, unitisation, convenience, and communication of the product.11 According to Paine[5] and Robertson[6], “packaging is a coordinated system of preparing goods for transport, distribution, storage, retailing, and end use. Packaging is the means of ensuring safe delivery to the ultimate consumer in sound condition at minimum cost. Packaging is a techno-economic function aimed at minimizing costs of delivery while maximizing sales.”

Packaging can be classified as primary, secondary, or tertiary.[7] Primary packaging is the packaging which is in direct contact with the product, while the secondary packaging is designed to hold many primary packages. A collection of primary or secondary packages on a pallet or a roll container is referred as tertiary packaging.[8] Many managers consider packaging as an unavoidable non-value-added cost with little or no strategic value. On the other hand, the packaging may have a major impact on logistics costs and performance. The key features of packaging include the type, cost, etc., which is linked to the value and the type of product.[9] For example, for high-value products, the packaging cost can be high whereas for the low-value products the packaging cost is relatively less and more affordable.

Information Processing. Converting data to information and processing it to make it viable for decision making is an essential element of the information system. Information processing is vital for the success of logistics management. The key features of information processing are information systems, controls, and forecasting. Processing of the data in the right manner helps in the right analysis of the data. It is vital to process the logistics data accurately, efficiently, and satisfactorily. Data processing errors in logistics can result in flawed decision making, wrong forecasting, increased inventory costs, stock-outs, and ultimately, customer dissatisfaction.

Source: Richard R. Still, Edward W. Cundliff, Normal A. P Govoni, Sandeep Puri (2017), Sales and Distribution Management: Decisions, Strategies, and Cases, Pearson; Sixth edition.

Some truly nice and utilitarian information on this website, besides I conceive the design and style contains great features.