The production/operations function of a business consists of all those activities that transform inputs into goods and services. production/operations management deals with inputs, transformations, and outputs that vary across industries and markets. A manufacturing operation transforms or converts inputs such as raw materials, labor, capital, machines, and facilities into finished goods and services. The extent to which a manufacturing plant’s output reaches its potential output is called capacity utilization, a key strategic variable. The higher the capacity utilization, the better; otherwise, equipment may sit idle.

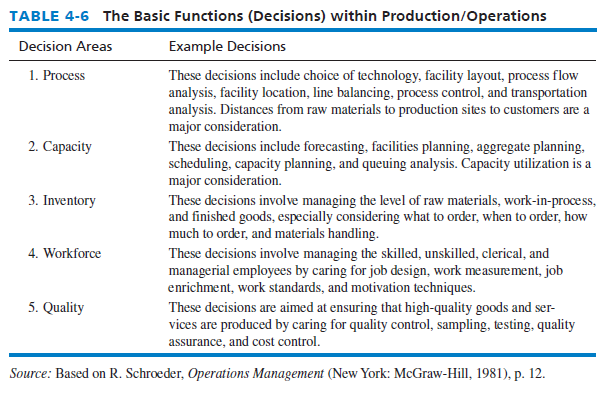

As indicated in Table 4-6, Roger Schroeder suggests that production/operations management comprises five functions or decision areas: process, capacity, inventory, workforce, and quality.

Production/operations activities often represent the largest part of an organization’s human and capital assets. In most industries, the major costs of producing a product or service are incurred within operations, so production/operations can have great value as a competitive weapon in a company’s overall strategy. Strengths and weaknesses in the five functions of production can mean the success or failure of an enterprise.

Increasingly in production settings, a new breed of robots called collaborative machines, are working alongside people. The robots, priced as low as $20,000 and becoming widely used even in small businesses, do not take lunch breaks or sick days or require health insurance, and they can work nonstop all night tirelessly if needed. Unlike larger robots that cost much more, collaborative machines are more flexible, oftentimes doing one task one day and a different task the next day. At Panek Precision Inc., an Northbrook, Illinois-based machine shop, Mr. Panek states, “Having robots has allowed us to move our existing workers into more useful tasks, such as monitoring more-advanced machines that require human tending.” Workers are generally quite receptive to collaborative machines, even giving them names, such as “Fred” at Stuller Inc., a jewelry factory in Lafayette, Louisiana, and “Baxter” at K’NEX Brands, a toy maker in Hatfield, Pennsylvania.26

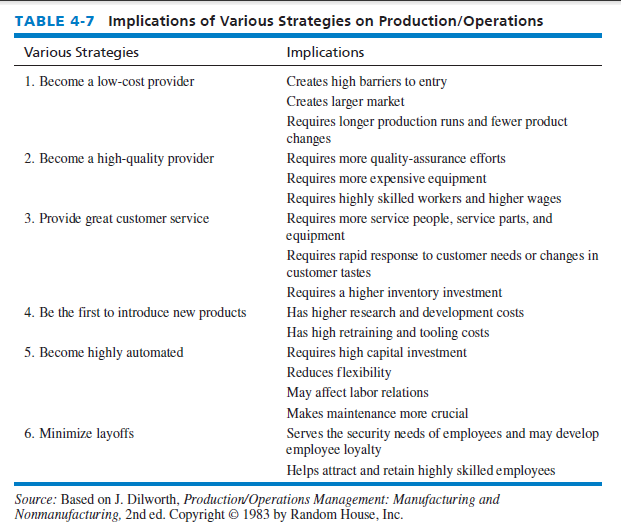

Many production/operations managers are finding that cross-training of employees can help their firms respond faster to changing markets. Cross-training can increase efficiency, quality, productivity, and job satisfaction. For example, at General Motors’ Detroit gear and axle plant, costs related to product defects were reduced 400 percent in 2 years as a result of cross-training workers. As shown in Table 4-7, James Dilworth has outlined implications of several types of strategic decisions a company might make.

1. Production/Operations Audit Checklist

Questions such as the following should be examined:

- Are supplies of raw materials, parts, and subassemblies reliable and reasonable?

- Are facilities, equipment, machinery, and offices in good condition?

- Are inventory-control policies and procedures effective?

- Are quality-control policies and procedures effective?

- Are facilities, resources, and markets strategically located?

- Does the firm have technological competencies?

2. Research and Development

The fifth major area of internal operations that should be examined for specific strengths and weaknesses as input into formulating strategies is research and development (R&D). Many firms today conduct no R&D, and yet many other companies depend on successful R&D activities for survival. Firms pursuing a product-development strategy especially need to have a strong R&D orientation. High-tech firms, such as Microsoft, spend a much larger proportion of their revenues on R&D. A key decision for many firms is whether to be a “first mover” or a “late follower” (i.e., spend heavily on R&D to be the first to develop radically new products, or spend less on R&D by imitating/duplicating/improving on products after rival firms develop them).

Organizations invest in R&D because they believe that such an investment will lead to a superior product or service and will give them competitive advantages. Research and development expenditures are directed at developing new products before competitors do, at improving product quality, or at improving manufacturing processes to reduce costs. However, a recent study reported that the stock price appreciation of technology companies in the lowest third of R&D spending have consistently outperformed companies in the highest third over 1, 3, 5, and 10-year periods since 1977, with a 5-year average outperformance of 8 percent.27 In the study, some big R&D underspenders whose stock price significantly outperformed were Micron Technology, Seagate Technology, Western Digital, and Apple. the study reported in Investor’s Business Daily accents the need to formulate and implement an effective R&D spending strategy consistent with overall corporate strategy and objectives.

Effective management of the R&D function requires a strategic and operational partnership between R&D and the other vital business functions. A spirit of partnership and mutual trust between general and R&D managers is evident in the best-managed firms today. Managers in these firms jointly explore; assess; and decide the what, when, where, why, and how much of R&D. Priorities, costs, benefits, risks, and rewards associated with R&D activities are discussed openly and shared. the overall mission of R&D has thus become broad based, including supporting existing businesses, helping launch new businesses, developing new products, improving product quality, improving manufacturing efficiency, and deepening or broadening the company’s technological capabilities.28

3. Internal and External Research and Development

Four approaches to determining research and development budget allocations commonly are used: (1) financing as many project proposals as possible, (2) using a percentage-of-sales method, (3) budgeting about the same amount that competitors spend for R&D, or (4) deciding how many successful new products are needed and working backward to estimate the required R&D investment. the strengths (capabilities) and weaknesses (limitations) of R&D play a major role in strategy formulation and strategy implementation.

Most firms have no choice but to continually develop new and improved products because of changing consumer needs and tastes, new technologies, shortened product life cycles, and increased domestic and foreign competition. A shortage of ideas for new products, increased global competition, increased market segmentation, strong special-interest groups, and increased government regulations are several factors making the successful development of new products more and more difficult, costly, and risky. In the pharmaceutical industry, for example, only one of every few thousand drugs created in the laboratory ends up on pharmacists’ shelves.

4. Research and Development Audit

Questions such as the following should be asked in performing a research and development audit:

- Does the firm have R&D facilities? Are they adequate?

- If outside R&D firms are used, are they cost effective?

- Are the organization’s R&D personnel well qualified?

- Are R&D resources allocated effectively?

- Are management information and computer systems adequate?

- Is communication between R&D and other organizational units effective?

- Are present products technologically competitive?

Source: David Fred, David Forest (2016), Strategic Management: A Competitive Advantage Approach, Concepts and Cases, Pearson (16th Edition).

What¦s Going down i’m new to this, I stumbled upon this I have discovered It positively helpful and it has helped me out loads. I hope to contribute & assist different users like its helped me. Good job.