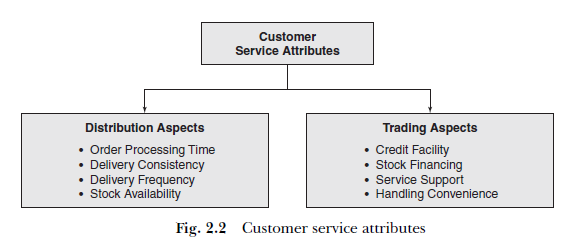

The most important and critical aspect of customer service is physical distribution of the product; that is, making the right product available at the right place and at the right time, followed by the motivation of service success facilitators such as channel members to complete the physical distribution. For FMCG or mass-consumed products wherein product distribution is dependent on the length and breadth of the channel needs the logistics programs customized to the requirements of the channel partners. For these programs to be successful, the channel members need to be serviced and motivated by the manufacturers. The services extended to this trading community require different attributes from those required for satisfying the end customers (see Figure 2.2).

1. Order Process Time

Order process time is the most important measure of customer service in physical distribution. It is the time between the placement of an order by the buyer and the supply of the material by the seller against an order. This involves the supply of all the material against the order placed within the agreed time frame, without any error either in documentation or physical supply. This customer service attribute helps in building a long-term buyer-seller relationship. The order processing time consists of the time required for registration of the order in the supplier’s system after thorough technical and commercial scrutiny; material allocation and pickup from the work-in-progress inventory, warehouse, or distribution centres; packing of material; documentation; and dispatch of material. The time consumed in each of these activities will depend on how well coordinated the various departments are and the speed of the information flow across the logistics supply chain.

2. Delivery Consistency

This refers to the consistency in maintaining the same delivery period for delivering the material to the buyer over a period of time. For example, if the supplier dispatches the material per the agreed delivery time for 97 orders against 100 repeat orders received during the year, it may be said that the supplier’s delivery consistency is 97 per cent, and as per the present industry norms it is an excellent delivery performance. Delivery consistency speaks of the degree of coordination in the various logistics arms of the seller’s firm and the efficiency and effectiveness of the logistical supply chain. The delivery consistency of suppliers has a direct effect on the inventory level at the buyer’s end. Inconsistency in deliveries may force the buyer to carry an excess inventory of raw materials and components as a precautionary measure and thereby block more funds. Subsequently, the buyer may look for an efficient source of supply to get rid of the inventory problem.

3. Delivery Frequency

The frequency of delivery is the key element in customer service. The customer does not want to carry an excess inventory but wants his operations to run without interruptions. As a result, the customer prefers frequent deliveries in small lots. This may increase transportation cost, but it reduces the inventory-related cost drastically, with the net result being a reduction in the overall supply chain cost. Another case is of the firm that may not have all the ordered items available in its stocks. In such a situation the supplier, with the consent of buyer, may supply the critical items first, followed by a consignment of the remaining items after they are made and are available for dispatch. The additional transportation cost may be borne by the supplier to compensate for the buyer’s inconvenience. The practice of frequent deliveries in small lots is quite common in retail chains.

4. Stock Availability

Stock availability is an important measure of customer service. With excess stocks, the supplier may extend an excellent service to the customer, but inventory-related cost reduces the profit margin of business operations. Hence the firm needs to strike a balance between the inventory level and the desired customer service level through integrated logistics operations. The reduction in stock holdings may be exercised through centralized inventory control from a single-mother warehouse by reducing field distribution warehouses at multiple locations. Centralization may help reduce administrative cost, operating cost, and manpower cost while simultaneously reducing inventory carrying costs at the various locations. Although transportation cost may go up, the net saving would be more than such an increase in costs.

5. Credit Facility

As a value added service, the supplier may offer credit facility to the buyer against the material dispatched. This is done for building long-term relations with the customer and to get repeat bulk business from the buyer. In case credit facility is industry trends and customer extending the payment beyond the agreed time frame, then the supplier may think about the scope for recovering the cost of blocked funds from the customer.

6. Stock Financing

Against bulk orders, as in the case of seasonal products, suppliers sometimes hold the inventory for the buyer for a longer time. Depending on the competition in the industry and the assurance of repeat orders from the buyer, a supplier may hold the inventory for a longer time, bearing the carrying cost as a value added service. This ultimately means indirectly financing the operations of the buyer, by shifting the cost element from buyer to seller.

In the competitive logistics industry, the warehouse service supplier finances the goods depositors by way of loans up to 30-50 per cent of the stocks deposited. This loan is made available at interest rates lower than that of banks. In the Indian context, warehouses attached to the cooperative sector industry extend loans to farmers up to 70 per cent of the value of the food grains deposited in the warehouse.

7. Service Support

Service support may be in terms of technical support for product installation, commissioning, process stabilizing, spare parts supply, and routine equipment check-up as part of the annual service contact. Service support is required to keep the downtime of the equipment very low, as it ultimately has a significant effect on productivity at the customer’s end. As a value addition, the supplier may extend technical support not only in the area related to his products, but in resolving the technical problems in the client’s manufacturing shop or by actively supporting a new product development process. If the supplier has a strong technical arm, he may extend technical support to the buyers in areas unrelated to his product line.

8. Handling Convenience

For the convenience of material handling and storage at the customer’s end, the supplier, may develop novel methods for product unitizing such as pallets, boxes, or cartons. These methods are customized to suit the existing product handling arrangement at the customer’s end. Alternatively, the supplier may help the customer in installation or development of a material handling system. This may help to reduce the material handling hassles and product damages at the buyer’s end.

Source: Sople V.V (2013), Logistics Management, Pearson Education India; Third edition.

I was studying some of your articles on this website and I think this web site is very informative ! Retain putting up.