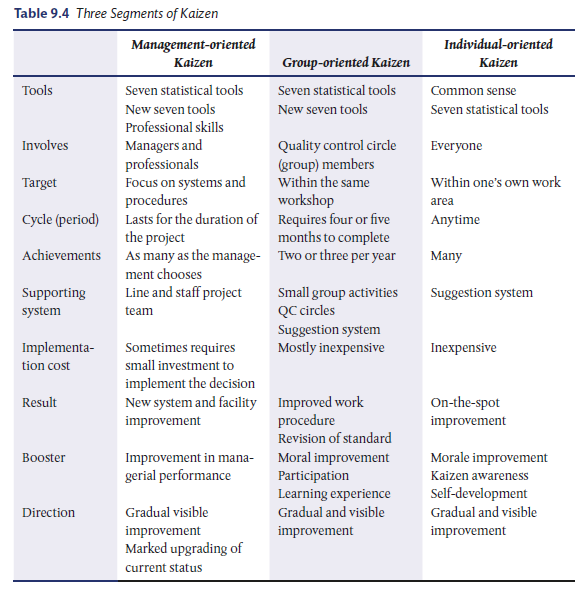

A well planned Kaizen programme can be broken down into three segments—management- oriented Kaizen, group-oriented Kaizen and individual-oriented Kaizen—depending on the complexity and the level of Kaizen. Table 9.4 elaborates and explains this aspect.

1. Management-oriented Kaizen

Management-oriented Kaizen is considered the first pillar of Kaizen. It is a crucial pillar, since it concentrates on the most important logistic and strategic issues and provides the momentum to keep up progress and morale.

Since Kaizen is everybody’s job, the manager must be engaged in improving his own job. Japanese management generally believes that a manager should spend at least 50 per cent of his time on improvement. The starting point of Kaizen is to identify “waste” in the worker’s motion. Management-oriented Kaizen also takes the form of a group approach such as Kaizen teams, project teams and task forces. However, these groups are quite different from quality control circles in that they are composed of management and staff, and their activities are regarded as a routine part of the management’s job.

The management should direct its effort to systems improvement as one of the most important tasks of management-oriented Kaizen. Systems improvement concerns such crucial areas of management as planning and control, decision-making processes, organization and information systems. Where the management has failed to establish such a system and has instead directed its efforts randomly and in bits and pieces, success has often been short lived. This is why top management commitment is indispensable when Kaizen is introduced. Many top executives believe that Kaizen comprises 50 per cent of the management’s job.

2. Group-oriented Kaizen

Group-oriented Kaizen is represented by small group activities such as quality control circles that use various tools to solve problems. The permanent approach also calls for the full PDCA cycle and demands that team members identify problem areas and also identify the causes, analyse them, implement and test new countermeasures and establish new standards and/or procedures.

Small group activities may be defined as informal voluntary small groups organized within the company to carry out specific tasks in the workshop. These small group activities take many forms, depending on their aims—big brother groups, big sister groups, QC circles, ZD movements, no-error movements, level-up movements, mini think tanks, suggestion groups, safety groups, workshop involvement movements, productivity committees, management-by-objectives groups and workshop talk groups. These small groups were often initially formed for the purpose of stimulating cross-development among its members. The advantages of small group activities are given below:

- Setting group objectives and working for their attainment strengthens the sense of teamwork.

- Group members share and coordinate their respective roles better.

- Communication between labour and management, as well as between workers of different ages, is improved.

- Morale is greatly improved.

- Workers acquire new skills and knowledge and develop more cooperative attitudes.

- The group is self-sustaining and solves problems that would otherwise be left to the management.

- Labour-management relations are greatly improved.

Although small group activities begin as informal and voluntary for the most part, today they have come to occupy a respected and legitimate position in the eyes of management.

3. Individual-oriented Kaizen

The suggestion system is a vehicle for carrying out individual-oriented Kaizen. Individual- oriented improvement is often regarded as a morale booster. The management does not always ask for immediate economic payback on each suggestion. Management attention and responsiveness are essential if workers are to become “thinking workers,” always looking for better ways to do their work. The suggestion system is an integral part of individual-oriented Kaizen. Top management must implement a well designed plan to assure that the suggestion system is dynamic. The following are some examples for suggestions in most of the companies:

- Improvements in one’s own work

- Savings in energy, material and other resources

- Improvements in the working environment

- Improvements in machines and processes

- Improvements in jigs and tools

- Improvements in office work

- Improvements in product quality

- Ideas for new products

Source: Poornima M. Charantimath (2017), Total Quality Management, Pearson; 3rd edition.

Hello! I simply want to offer you a big thumbs up for the

great information you have got right here on this post.

I am coming back to your website for more soon.

WONDERFUL Post.thanks for share..more wait .. …