The production system of an organization is that part, which produces products of an organization. It is that activity whereby resources, flowing within a defined system, are combined and transformed in a controlled manner to add value in accordance with the policies communicated by management. A simplified production system is shown above.

The production system has the following characteristics:

- Production is an organized activity, so every production system has an objective.

- The system transforms the various inputs to useful outputs.

- It does not operate in isolation from the other organization system.

- There exists a feedback about the activities, which is essential to control and improve system performance.

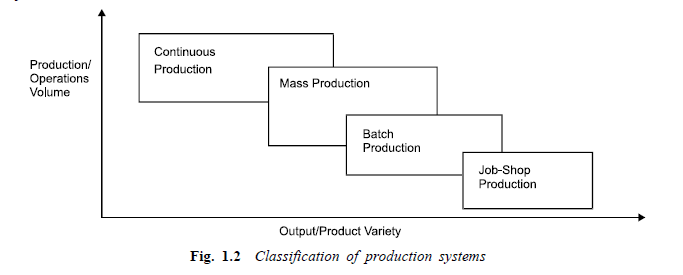

Classification of Production System

Production systems can be classified as Job Shop, Batch, Mass and Continuous Production systems.

1. JOB SHOP PRODUCTION

Job shop production are characterised by manufacturing of one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost. The distinguishing feature of this is low volume and high variety of products.

A job shop comprises of general purpose machines arranged into different departments. Each job demands unique technological requirements, demands processing on machines in a certain sequence.

Characteristics

The Job-shop production system is followed when there is:

- High variety of products and low volume.

- Use of general purpose machines and facilities.

- Highly skilled operators who can take up each job as a challenge because of uniqueness.

- Large inventory of materials, tools, parts.

- Detailed planning is essential for sequencing the requirements of each product, capacities for each work centre and order priorities.

Advantages

Following are the advantages of job shop production:

- Because of general purpose machines and facilities variety of products can be produced.

- Operators will become more skilled and competent, as each job gives them learning opportunities.

- Full potential of operators can be utilised.

- Opportunity exists for creative methods and innovative ideas.

Limitations

Following are the limitations of job shop production:

- Higher cost due to frequent set up changes.

- Higher level of inventory at all levels and hence higher inventory cost.

- Production planning is complicated.

- Larger space requirements.

Batch Production

Batch production is defined by American Production and Inventory Control Society (APICS) “as a form of manufacturing in which the job passes through the functional departments in lots or batches and each lot may have a different routing. ” It is characterised by the manufacture of limited number of products produced at regular intervals and stocked awaiting sales.

Characteristics

Batch production system is used under the following circumstances:

- When there is shorter production runs.

- When plant and machinery are flexible.

- When plant and machinery set up is used for the production of item in a batch and change of set up is required for processing the next batch.

- When manufacturing lead time and cost are lower as compared to job order production. Advantages

Following are the advantages of batch production:

- Better utilisation of plant and machinery.

- Promotes functional specialisation.

- Cost per unit is lower as compared to job order production.

- Lower investment in plant and machinery.

- Flexibility to accommodate and process number of products.

- Job satisfaction exists for operators.

Limitations

Following are the limitations of batch production:

- Material handling is complex because of irregular and longer flows.

- Production planning and control is complex.

- Work in process inventory is higher compared to continuous production.

- Higher set up costs due to frequent changes in set up.

2. MASS PRODUCTION

Manufacture of discrete parts or assemblies using a continuous process are called mass production. This production system is justified by very large volume of production. The machines are arranged in a line or product layout. Product and process standardisation exists and all outputs follow the same path.

Characteristics

Mass production is used under the following circumstances:

- Standardisation of product and process sequence.

- Dedicated special purpose machines having higher production capacities and output rates.

- Large volume of products.

- Shorter cycle time of production.

- Lower in process inventory.

- Perfectly balanced production lines.

- Flow of materials, components and parts is continuous and without any back tracking.

- Production planning and control is easy.

- Material handling can be completely automatic.

Advantages

Following are the advantages of mass production:

- Higher rate of production with reduced cycle time.

- Higher capacity utilisation due to line balancing.

- Less skilled operators are required.

- Low process inventory.

- Manufacturing cost per unit is low.

Limitations

Following are the limitations of mass production:

- Breakdown of one machine will stop an entire production line.

- Line layout needs major change with the changes in the product design.

- High investment in production facilities.

- The cycle time is determined by the slowest operation.

3. CONTINUOUS PRODUCTION

Production facilities are arranged as per the sequence of production operations from the first operations to the finished product. The items are made to flow through the sequence of operations through material handling devices such as conveyors, transfer devices, etc.

Characteristics

Continuous production is used under the following circumstances:

- Dedicated plant and equipment with zero flexibility.

- Material handling is fully automated.

- Process follows a predetermined sequence of operations.

- Component materials cannot be readily identified with final product.

- Planning and scheduling is a routine action.

Advantages

Following are the advantages of continuous production:

- Standardisation of product and process sequence.

- Higher rate of production with reduced cycle time.

- Higher capacity utilisation due to line balancing.

- Manpower is not required for material handling as it is completely automatic.

- Person with limited skills can be used on the production line.

- Unit cost is lower due to high volume of production.

Limitations

Following are the limitations of continuous production:

- Flexibility to accommodate and process number of products does not exist.

- Very high investment for setting flow lines.

- Product differentiation is limited.

Source: KumarAnil, Suresh N. (2009), Production and operations management, New Age International Pvt Ltd; 2nd Ed. edition.

Everything is very open with a precise explanation of the issues.

It was really informative.

Your website is very useful.

Many thanks for sharing!

Great web site you have got here..

It’s difficult to find good quality writing

like yours nowadays. I truly appreciate individuals

like you! Take care!!

I have been searching for this all this time around.

Pleased I have found it here. Thank you so much!

I have discovered good posts here. I like the way you describe it.

Nice!